4 - Set-Up

4. 14

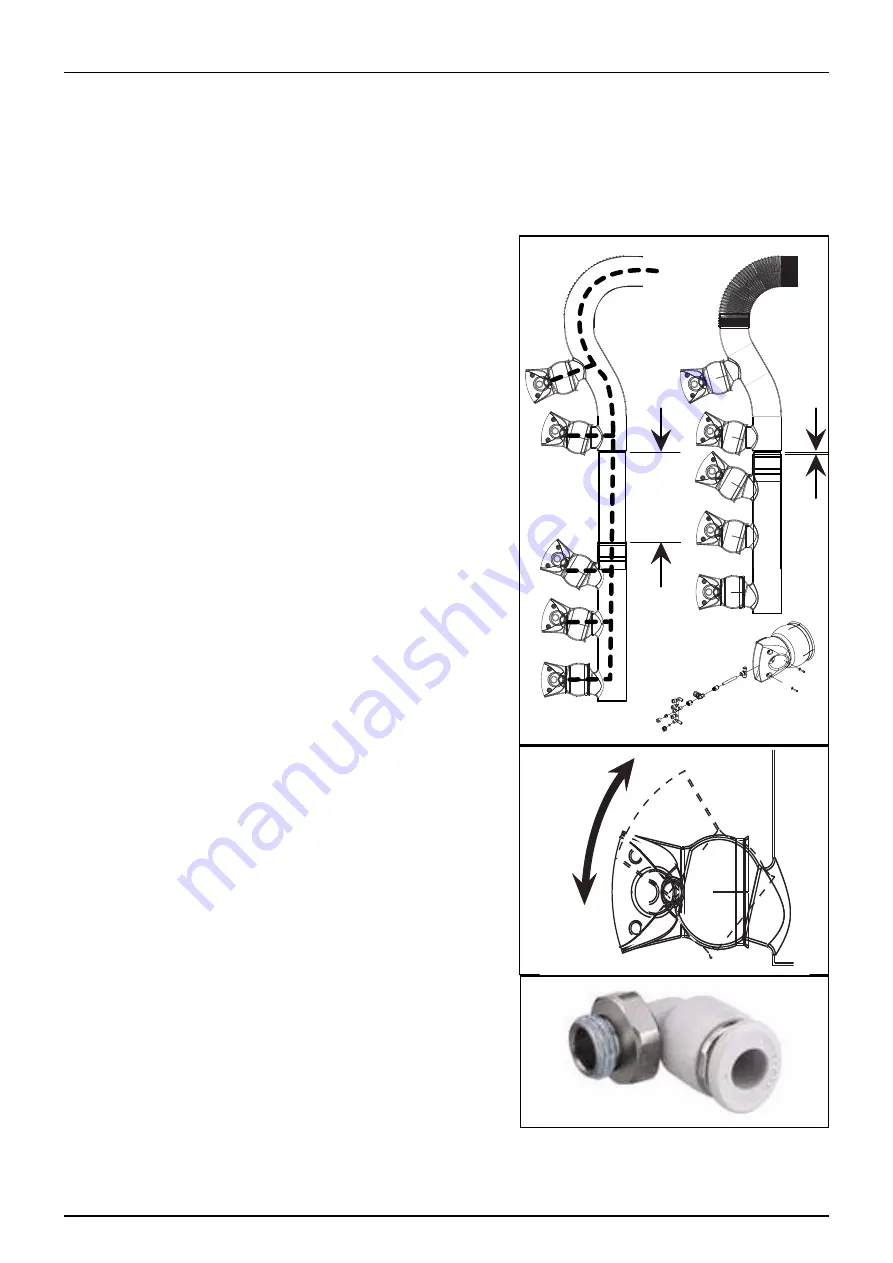

Adjustable Boom Tube Length & nozzle positioning

The boom tubes and nozzles for the MERCURY COVAMAX include features that enable the operator to set the

machine to suit their particular spray application needs. These features are;

•

Boom Tube length adjustment

•

Positional Nozzles

Boom Tube Adjustment

The boom tubes are able to be trimmed to length to suit your

spraying needs. By removing the band clamp fitted to the lower

section of the boom tubes and then removing the lower section,

the upper section may be cut to the desired length then

reassembled with the lower section.

Located inside the boom tubes and nozzle shrouds are fluid supply

lines and nozzle body assemblies. Care should be taken not to

damage any of these items when making adjustments to the boom

tubes.

Nozzle Positioning

The ball and socket joint design of the nozzles allows for

independent positioning of the nozzles to aid even dispersion of

spray to gain better results in your spray application.

Fluid Hoses

The high pressure tubes inside the booms that feed fluid to the

nozzle bodies are all connected through the use of ‘push-in’ quick

release fittings similar to the picture shown. To disconnect a tube

from the fitting, push the plastic ring in towards the body of the

fitting and pull the tube out of the fitting. If the tube will not

release try slightly pushing the tube into the fitting then back out

again while making sure the plastic ring is pushed in.

Содержание Mercury Covamax series

Страница 1: ...MERCURY COVAMAX Operator Instruction Manual 67002404 100 HAU 08 2009 www hardi com au...

Страница 10: ...Table of Contents TOC 8...

Страница 18: ...2 Safety 2 6...

Страница 88: ...6 Maintenance 1 18 Maintenance Activity Record Date Service Performed...

Страница 92: ...7 Fault Finding 1 4...

Страница 95: ...8 Technical Specifications 8 3 50 mesh 0 30 mm BLUE 80 mesh 0 18 mm RED 100 mesh 0 15 mm YELLOW...

Страница 100: ...8 Technical Specifications 8 8...