HAMWORTHY HEATING LTD

42

FLEET H series

500001212/F

10 SERVICING

A competent person registered for working on non

domestic gas appliances should check and ensure that

the flue, its support and terminal, the ventilation to the

boiler house, safety valve, drain, water filter if fitted,

pressure gauge, etc.; are in a serviceable and working

condition and still comply with the relevant standards

and codes of practice - see

Section 4.

10.1 Regular servicing is recommended

, preferably

by a Hamworthy appointed person, and at least

annually, to ensure trouble free operation.

For Fleet boilers, Hamworthy would recommend an

additional 6 monthly examination following

commissioning, acknowledging site conditions and

running hours.

Although cleaning of flueways may not be necessary on

a yearly basis, it is important that all controls and safety

features are checked for correct operation.

Note:-

Measuring flue gas CO

2

and gas temperatures

will give an indication of the state of the boiler flueways

and waterways. Results should be compared with

previously measured values to establish possible loss of

efficiency.

10.2 Annual Service

Before servicing the boiler, the following procedure must

be carried out :-

WARNING: Isolate all electrical supplies and turn off

the gas service valve.

1)

Open the front casing by turning the 1/4 turn latches

with a flat bladed screw driver. Note the latch

mechanism passes through slots in the chassis top and

bottom.

Once removed access is gained to the controls panel,

the heat exchanger components and the combustion

system assembly.

2)

Disconnect the H.T and flame probe connectors from

the respective probes.

3)

Disconnect the fan power supply and control leads

from the fan taking care with the latch on each

connector.

4)

Check that the gas service valve is closed, then undo

the compression union on the inlet to the gas valve.

5)

Carefully disengage the flexible air inlet duct from the

venturi and remove the electrical plug from the gas

valve.

6)

Remove the 3 M6 socket head screws securing the

fan /burner duct assembly to the heat exchanger and

carefully remove the assembly and the sealing gasket.

Carefully remove the burner from the heat exchanger,.

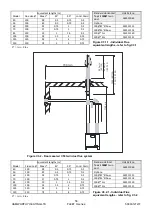

7)

Remove and inspect H.T. electrode and flame probe,

ensure they are free from debris or deposits. – See

Figures 10.2. 10.2.1 & 10.2.2

8)

Check the burner and clean using a soft brush if

required (if possible use a vacuum cleaner to remove

the dust from inside the burner tube). After cleaning the

inside, the burner tube can be washed using a soapy

water solution. Tap the burner flange firmly downwards

on a block of wood to dislodge any residual debris from

inside the burner tube. A damaged or cracked burner

should be replaced.

Note:-

Do not use a wire brush to clean the burner.

9)

Carefully remove the insulation pad from the heat

exchanger back plate (accessed through the burner

cavity) and replace with a new pad ensuring the edges

are ‘tucked in’ to the gap past the last section

10)

Separate the gas valve / venturi from the fan inlet

noting it’s orientation and inspect the fan scroll and

impellor, clean and check for damage.

11)

Clean and check the venturi for contamination.

12)

Remove the fan from the burner duct and inspect

the non return valve in the duct for smooth operation.

13)

Separate the inlet flange /elbow fitting from the gas

control valve by removing the 4 M5 socket cap head

screws. Check that the mesh inlet filter in the gas valve

is clear of debris, remove any foreign objects caught in

the filter.

Re-assemble in reverse order taking care to inspect and

if necessary, replace any o-rings, gaskets or seals.

Refer to

Section 8, Commissioning and Testing

, and

test all gas joints broken or disturbed for soundness

before firing.

Carry out a combustion check by testing the flue gas

CO

2

and CO levels as detailed in

Section 8.2.

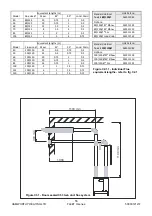

10.3 Four Year Service

Repeat the annual service as previously described but

do not refit any components to the heat exchanger.

Isolate the boiler flow and return connections from the

heating system.

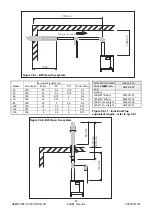

10.3.1

To clean the heat exchanger, the use of a high

pressure water hose (40-80 psi) is recommended for

the primary flue gas path. However provision must be

made for the drainage of water used in this process. At

the rear of the boiler remove the condensate drain trap

assembly from the flue elbow. Connect a hose (32mm

id.) to the flue elbow and take to a suitable drain or

receptacle. The cleaning water and any debris will exit

the sump through this opening.

To clean the condensing flue gas path, isolate the boiler

from the heating system and drain the boiler heat

exchanger using the drain valve provided in the return

pipe. Disconnect the electrical supply to the pump,

return sensor and the flow switch. Carefully support the

pump, disconnect the unions and remove the pump.

Remove the 2 M6 screws securing the return elbow /

pipe assembly to the heat exchanger and carefully

remove the assembly.

Remove the 4 screws (M8) securing the heat

exchanger assembly to the chassis backplate.

Disconnect the heat exchanger flow connection from

the heating system and the flue pipe from the sump

elbow and carefully slide the heat exchanger assembly

Содержание F100H

Страница 2: ......

Страница 35: ...HAMWORTHY HEATING LTD 29 FLEET H series 500001212 F Figure 8 2 1 3 Operation and display philosophy...

Страница 44: ...HAMWORTHY HEATING LTD 38 FLEET H series 500001212 F Figure 8 3 11 Operating phases...

Страница 75: ...HAMWORTHY HEATING LTD 69 FLEET H series 500001212 F NOTES...

Страница 77: ...Please complete the information on the Registration Card cut out and return to Hamworthy Heating Ltd...

Страница 78: ......

Страница 79: ......