HAMWORTHY HEATING LTD

10

FLEET H series

500001212/F

4.3 Flue System

The Fleet flue systems supplied by Hamworthy are non UV stabilised polypropylene and

are therefore suitable for internal use only. For external flue runs and termination, either

use the dedicated kits supplied by Hamworthy or refer to a chimney specialist .

Flue termination, routing and construction must comply with the requirements of the

Clean Air Act 1956, BS 6644, BS 5440 and IGE/UP/10 where applicable.

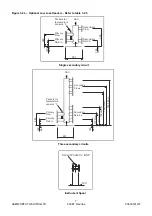

Individual modules must be flued using the concentric or twin duct systems provided or

connected into conventional chimney system suitable for condensing application.

Fleet boilers are suitable for open flue (type B

23

) installation, drawing combustion air

from the plant room, or room sealed, twin duct (type C

53

) installation - see section 5.2.

For type B

23

installations, the maximum number of modules firing into a common

chimney is 9. For larger installations refer to HHL Technical. The flue system must be

designed to limit the max. suction (cold) to 30Pa negative, measured at the connection to

the boiler. If the suction is greater than 30Pa, refer to HHL technical.

This condition must then be checked hot and with all boilers firing, the max. pressure at

the connection to the boiler should be 150Pa positive.

In the event that the flue system

when hot does generate a suction, the max. suction is 100Pa.

For type B23 installations the Hamworthy air inlet filter MUST always be fitted .

Refer to Appendix C.

Any stabiliser fitted must be in or close to the vertical chimney.

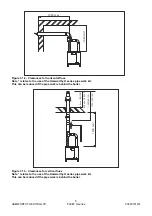

Due to the low flue gas temperature, (~50°C) condensation will occur in the flue, flue

materials must be non-corrosive and utilise fully sealing joints.

Adequate facilities must be provided for draining the flue condensation from the flue

system using the components available from HHL - refer to Appendix C. For short flue

runs (<1m) it is not practical to provide drainage from the flue system.

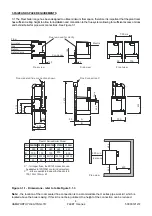

Horizontal runs of flue must provide condense drainage from the flue /chimney and must

slope at 3° (50mm/m) along the horizontal length, towards the boiler. For longer flue

systems (>1m), the flue system MUST NOT drain through the boiler - see section 5.2 .

For multiple boilers into a common flue header, the common header must slope at 3°

back to the boilers and provision made to remove condensate from the header - see

section 5.2 .

Horizontal flue runs must be kept as short as possible and be inclined at minimum 3°

(50mm/m) towards the boiler.

For maximum equivalent flue lengths, refer to Appendix C.

Any flue must be self-supporting and separable from the boiler for servicing

requirements.

Note: Due to high thermal efficiency of the Fleet boiler and the resultant low flue gas

temperatures there will be visible pluming of the flue gases at the flue termination. This

is likely even when the boiler is not operating at condensing temperatures.

Fan dilution - the design must provide for the use of balancing and trim dampers,

and their location and operation must be such that the constraints detailed above

can be met. Care must be taken to ensure that the fan performance is matched to

deliver the appropriate dilution, whilst ensuring that excessive suction is not

applied to the boilers. If in doubt, refer to HHL Technical.

Содержание F100H

Страница 2: ......

Страница 35: ...HAMWORTHY HEATING LTD 29 FLEET H series 500001212 F Figure 8 2 1 3 Operation and display philosophy...

Страница 44: ...HAMWORTHY HEATING LTD 38 FLEET H series 500001212 F Figure 8 3 11 Operating phases...

Страница 75: ...HAMWORTHY HEATING LTD 69 FLEET H series 500001212 F NOTES...

Страница 77: ...Please complete the information on the Registration Card cut out and return to Hamworthy Heating Ltd...

Страница 78: ......

Страница 79: ......