6

221992D

1.3 Statutory Requirements

The installation of this appliance must be carried out by a

competent person and must be in accordance with the relevant

requirements of the current issue of:

Manufacturer’s instructions supplied.

The Gas Safety (Installation and Use) Regulations, Building

Regulations, Local Water Company Bye-laws, The Building

Standards (Scotland) Regulations, (applicable in Scotland),

Health and Safety at Work Act, Control of Substances Hazardous

to Health, Electricity at Work Regulations and any applicable

local regulations.

Detailed recommendations are contained in the current issue of

the following British Standards and Codes of Practice,

BS6891, BS5440 Part 1 and 2, BS6798, BS5449, BS5546,

BS6700, BS7478, BS7593, BS7671.

Manufacturer’s instructions must not be taken as overriding

statutory requirements.

1.4 B.S.I Certification

This boiler is certificated by B.S.I., for safety and performance.

It is, therefore, important that no alteration is made to the boiler

unless agreed, in writing, by Halstead Boilers Ltd.

Any alteration not approved by Halstead Boilers Ltd., could

invalidate the B.S.I. certification, boiler warranty and could

infringe the current issue of the Statutory Requirements.

1.5 Gas Supply

The gas installation should be fitted in accordance with the

current issue of BS6891.

The supply from the governed meter must be of adequate size

to provide a steady inlet working pressure of 20mbar (8in wg) at

the boiler.

On completion test the gas installation using the pressure drop

method and suitable leak detection fluid, purge in accordance

with the current issue of BS6891.

1.6 Electrical

WARNING. This boiler must be earthed.

The electrical installation must be carried out by a competent

person. All external components shall be of the approved type

and shall be connected in accordance with the current issue of

BS7671 and any local regulations which apply.

Connection of the boiler and any system controls to the mains

supply through an unswitched shuttered socket outlet and 3A

fused 3 pin plug, both to the current issue of BS1363.

Alternatively, a 3A fused double pole isolating switch may be

used, having a minimum double pole contact separation of

3mm, serving only the boiler and system controls.

Heat resistant cable of at least 0.75mm

2

(24/0.20mm), to the

current issue of BS6500 Table 16, must be used for all

connections within the boiler casing, to the control box, pump

etc.

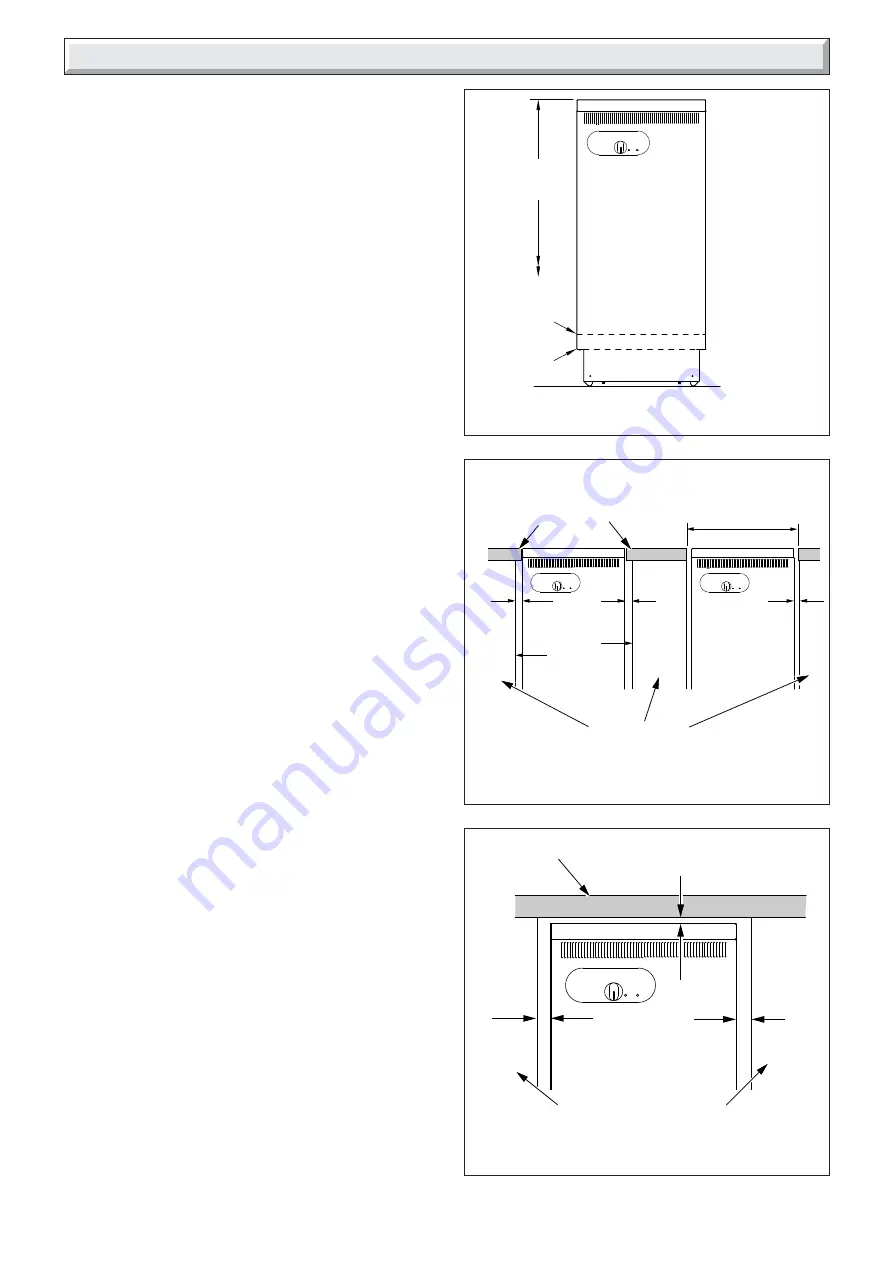

BOILER CASING HEIGHT(S)

Diagram 1.3

BOILER

CASING

ALTERNATIVE

HEIGHT

POSITIONS

MIN.

MAX.

To

floor

level

FLOOR LEVEL

9922

1 General Data

Diagram 1.4

Diagram 1.5

MINIMUM CLEARANCES

LEVEL WITH WORKTOP

MINIMUM CLEARANCES

UNDER WORKTOP, FIXTURES

9923

407 MIN.

407 MIN.

CUPBOARDS

WORKTOP

10124

10

10

10

10

CUPBOARD

CUPBOARD

10

WORKTOP OR

FIXTURE

BOILER

BOILER

5

MAX.900

MIN. 860