26

221992D

10 Replacement of Parts

IMPORTANT NOTES

REMEMBER, When replacing a part on this appliance, use only

spare parts that you can be assured conform to the safety and

performance specification that we require. Do not use

reconditioned or copy parts that have not been clearly authorised

by Halstead Boilers Ltd.

Replacement of parts must only be carried out by a competent

person.

Before removing or replacing any parts, turn off the gas supply

at the gas service cock, see diagram 8.2 and isolate the

electrical supply to the appliance.

Unless stated otherwise, all parts are replaced in the reverse

order to removal.

After replacing any parts always test for gas soundness and if

necessary carry out functional check of controls.

10.1 Electrical Thermistor

Remove front panel to gain access, see section 6.8.

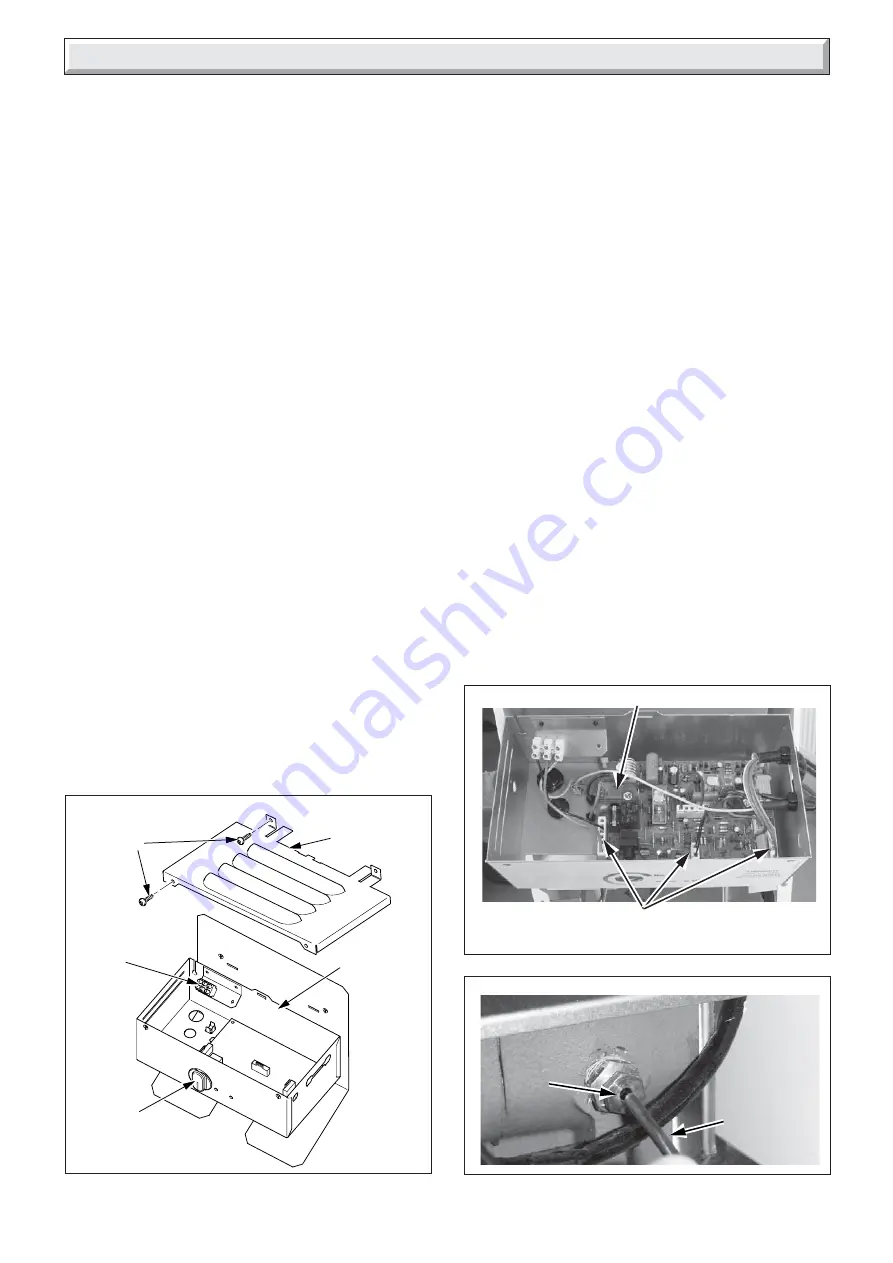

Remove control box cover by undoing the four securing screws

(two on control box, two on the heat shield) and lift off, see

diagram 10.1.

Remove thermistor lead from retaining clip, located on the

control box support bracket, see diagram 8.3.

Release strain relief grommet securing thermistor lead at the

side of control box.

Disconnect the thermistor electrical plug from the control board

(P.C.B) slightly bending back the retaining latch to allow

withdrawal, see diagram 10.2.

Remove the retaining wire and withdraw the electrical thermistor

from its phial, see diagram 10.3.

Draw the thermistor lead followed by the thermistor out though

the control box case.

Re-assembly note. When fitting the thermistor make sure it is

fully inserted into the phial, see diagram 10.3. Take care when

re-threading retaining wire so as not to damage thermistor.

10.2 Control Board (P.C.B)

Remove front panel to gain access, see section 6.8.

Remove control box lid by undoing the four securing screws

(two on control box, two on the heat shield) and lift off, see

diagram 10.1.

CONTROL

BOX

COVER

CONTROL

BOX

SECURING

SCREWS

TERMINAL

BLOCK

Diagram 10.1

9905

ELECTRICAL

PLUGS

Diagram 10.2

PCB

Diagram 10.3

PHIAL

POCKET

THERMISTOR

0000

BOILER

TEMPERATURE

CONTROL

Carefully pull the boiler temperature control knob away from the

P.C.B.

Disconnect the electrical plugs from the control board (PCB)

slightly bending back the retaining latches to allow withdrawal,

see diagram 10.2.

Disconnect ignition lead.

Carefully pull the board away from its supports bending back

slightly the retaining latches.

When refitting refer to wiring diagram 9.4.

Take care when replacing the burner temperature control knob

by supporting the potentiometer on the P.C.B.

10.3 Electrode

Refer to the relevant paragraphs of the servicing section to

remove the burner from combustion chamber.

To remove the electrode, unscrew from the retaining bracket,

see diagram 8.12.

Take the electrode out from below and remove the ignition lead.

When removing and replacing the electrode take care not to

damage it.

When refitting, check spark gap, see diagram 8.12.

10.4 Multifunctional Control

Remove front panel to gain access, see section 6.8.

Remove the securing screw and disconnect the electrical plug,

see diagram 10.4.

Disconnect the gas cock, on the left hand side.

Support the multifunctional control, remove the four screws (2

long, 2 short) from the flanged connection at the right hand side.

Remove and discard the original “O” ring from the flanged

connection and fit the new “O” ring supplied, into recess, before

fitting the replacement multifunctional control.

After assembly test for gas soundness and purge in accordance

with the current issue of BS6891.