24 / 35

Hakki Pilke XL - Conveyor

Translated

version 4-2021

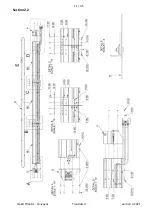

Figure 3a.

The inclination of the conveyor can be adjusted by turning the winch (Figure 3a) clockwise to increase the

conveyor angle or anticlockwise to decrease the angle. Before using the winch, detach the locking rods and

pins (2 pcs each) in Figure 3a. After adjustment, always lock the conveyor to rest on the locking rods and

pins by inserting them in the closest possible holes.

Never leave the conveyor suspended from the winch

alone!

2.5.

Adjusting the conveyor belt

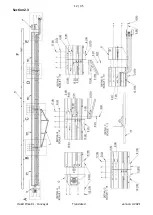

The tightness (and alignment) of the conveyor belt can be adjusted as follows:

1.

Loosen the tightening nut (upper) indicated by the arrow in Figure 4 from both sides.

2.

Tighten/loosen the belt with the lower nut in Figure 4 (the same amount on both sides of the belt).

If the belt is crooked, loosen the nut (in relation to the spring) on the side towards which you wish

to align the belt.

3.

When the conveyor belt is at the correct tension and properly aligned, tighten the fastening nuts

(Figure 4) tightly against each other on both sides. Note! Do not overtighten the belt

–

the spring

must have room to compress and expand. Note! If you run out of clearance to tension the belt, use

the other fastening holes at the connection point.

Содержание XL Conveyor 1

Страница 9: ...9 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 1...

Страница 10: ...10 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 2 1...

Страница 11: ...11 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 2 2...

Страница 12: ...12 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 2 3...

Страница 13: ...13 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 3...

Страница 14: ...14 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 4...

Страница 15: ...15 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 5 1...

Страница 16: ...16 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 5 2...

Страница 17: ...17 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 6 1...

Страница 18: ...18 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 6 2...

Страница 19: ...19 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 6 3...

Страница 20: ...20 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 7...