Содержание GE Connect Series

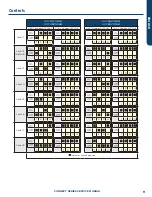

Страница 17: ...CONNECT SERIES SERVICE MANUAL 15 ENGLISH Troubleshooting Model AUH4860ZGDA ...

Страница 28: ...CONNECT SERIES SERVICE MANUAL 26 ENGLISH Troubleshooting AUH4860ZGDAA ...

Страница 90: ...CONNECT SERIES SERVICE MANUAL 88 ENGLISH Maintenance AUH4860ZGDA ...

Страница 92: ...CONNECT SERIES SERVICE MANUAL 90 ENGLISH Maintenance IDU Exploded View and Parts Lists UUY24ZGDAA UUY36ZGDAA ...