38

39

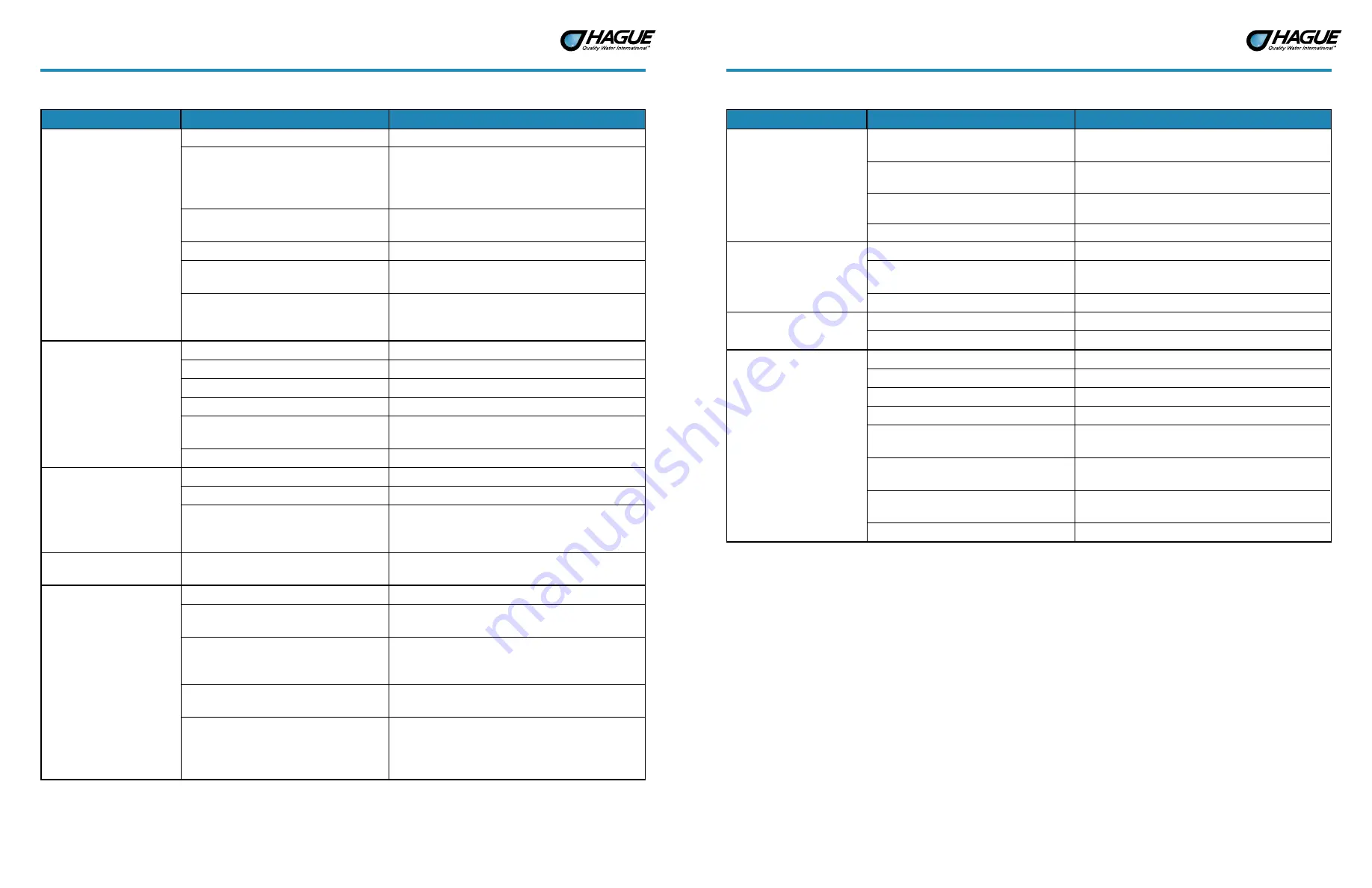

Troubleshooting

Problem

Possible Cause

Solution

No soft water after

regeneration

No salt in brine cabinet

Add salt

Sediment in brine cabinet has plugged the

brine line and air check/draw tube

Remove the brine line and flush clean

Remove the air check/draw tube and flush with clean

water. Clean injector assembly. Clean any sediment

from brine cabinet

Flow control is plugged

Remove brine piston housing and clear debris from the

flow control

Drain line is pinched, frozen, or restricted

Straighten, thaw, or unclog the drain line

Clogged injector assembly

Remove injector cap and clean nozzle and throat with

a wooden toothpick. Replace throat if removed

Salt bridge has formed due to high humidity

or the wrong kind of salt

Test with a blunt object like a broom handle. Push the

handle into the salt to dislodge the salt bridge, or use

hot water around the inside perimeter to loosen salt

No soft water

The bypass valve is in the Bypass position

Place the bypass valve in the Service position

Appliance is plumbed backward

Check that appliance is plumbed correctly

Extended power outage

Reset the time of day

Water hardness has increased

Re-test the water and re-enter a new setting number

Not metering water

Flow should be indicated with water usage. If no flow,

see below

Blending dial is open

Make sure blending dial is closed

No flow is indicated when

water is flowing

The bypass valve is in the Bypass position

Place the bypass valve in the Service position

Appliance is plumbed backward

Check that appliance is plumbed correctly

Sensor not receiving signal from magnet on

turbine

Remove sensor from bypass housing. Test with

magnet on either flat side of sensor. If flow is indicated,

check turbine. If no flow, replace sensor

Flow indicated when water

is not being used

The household plumbing system has a leak Repair the leak

No read-out in display

Electric cord is unplugged

Plug in the transformer

No electric power at outlet

Check power source. Make sure outlet is not controlled

by a switch

Defective transformer

Test with volt meter for 12 VAC at control. If less

than 10 VAC or greater than 14 VAC, replace the

transformer

Defective circuit board

With 12 VAC present at controller, replace the

controller

High ambient room temperature. If the

temperature exceeds 120°F (49°C), the

display will blank out. This does not affect

the operation of the controller

No action necessary

Troubleshooting

Problem

Possible Cause

Solution

Appliance stays in

regeneration

Controller not attached properly

Make sure the controller is pushed all the way onto the

drive end cap

Defective magnet disk

Replace magnet disk

Foreign object in main control valve

Remove foreign object(s) from the main control valve

Broken valve assembly. Motor running

Repair the drive end cap

Excess water in brine tank

Restricted, frozen, or pinched drain line

Remove restriction, thaw, or straighten drain line

Plugged brine line, brine line flow control, or

air check/draw tube

Clean flow control, air check/draw tube, and brine line.

Clean any sediment from the brine cabinet

Plugged injector assembly

Clean or replace injector. Replace throat if removed

Not regenerating in proper

sequence

Magnet disk defective

Replace magnet disk

Defective controller

Replace controller

Salty water (pink water

from iron filter)

Plugged injector

Replace injector screen, nozzle, and throat

Low water pressure

Maintain minimum pressure of 20 psi (1.4 bar)

Drain line or flow control is restricted

Remove restriction

Brine line restricted or crimped

Remove restriction, replace if crimped

Excessive amount of water in brine cabinet Verify correct water level relative to salt setting. Check

brine line and fittings for loose connections

Insufficient rinse time

Check mode setting chart for proper brine rinse time.

Adjust time, if necessary

Intermittent pressure drop from feed source Install check valve on the inlet water line to the

appliance (Check local plumbing codes first)

Brine valve drips water back to brine tank

Clean brine valve housing, replace piston assembly