VII.

SERVICE AND MAINTENANCE

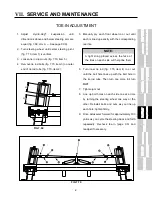

1. Remove wheel assembly from hub and

disassemble as shown in figure 7.39. Bearing

cups may remain in hub.

2. Thoroughly clean bearing with adequate cleaning

solvent and blow dry with compressed air. Take

care not to spin the bearings with the

compressed air.

3. Check bearings for wear; if bad, replace.

4. Grease inner bearing adequately with bearing

grease and install on back side of hub assembly

with inner bearing seal.

5. Install hub assembly on spindle.

6. Grease outer bearing adequately with bearing

grease and install in hub with washer and spindle

nut.

7. Tighten nut first by hand and then with a wrench

until you feel a slight drag while turning the hub.

This will seat the bearings.

8. Back nut off slowly until you notice slight side

play or hub “wobble.” Retighten nut until “wobble”

is unapparent and there is no drag.

9. Install cotter pin, dust cap, and wheel.

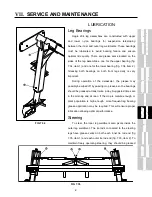

Four Blade Male Row Cutters

Grease both upper (fig. 7.40, item 1) and lower

(fig. 7.40, item 2) shaft bearings 4 times a day.

Suggested times are morning, mid-morning, noon,

and mid-afternoon.

LUBRICATION CONTINUED

FIG 7.40

1

2

FIG 7.39

1

6

2

7

3

8

5

9

10

4

11

x

Tire Pullers

1 – Puller spindle

2 – Inner bearing seal

3 – Inner bearing

4 – Inner bearing cup

5 – Bearing hub

6 – Outer bearing cup

7 – Outer bearing

8 – Washer

9 – Spindle nut

10 - Cotter pin

11 - Dust cap

Содержание 204

Страница 133: ...x IX TROUBLE SHOOTING TASSELTROL LS SYSTEM ELECTRICAL CONTINUED FIG 9 1 1 2...

Страница 134: ...x IX TROUBLE SHOOTING NOTES...

Страница 140: ...138 NOTES...

Страница 141: ...x...