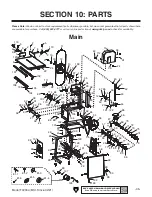

BUY PARTS ONLINE AT GRIZZLY.COM!

Scan QR code to visit our Parts Store.

REF PART #

DESCRIPTION

REF

PART #

DESCRIPTION

1

PT32304001

MEAT PUSHER

62

PT32304062

KEY 6 X 6 X 70

2

PT32304002

CAP SCREW M6-1 X 16

63

PT32304063

MEAT GRINDER SPINDLE

3

PT32304003

PUSHER SHAFT 248MM

64

PT32304064

ROLL PIN 4 X 40

4

PT32304004

SHAFT SUPPORT BRACKET

65

PT32304065

BALL BEARING 6203ZZ

5

PT32304005

KNOB BOLT M6-1 X 20, 8-LOBE, D30

66

PT32304066

MEAT GRINDER MOUNTING BRACKET

6

PT32304006

TABLE 23-1/2" X 18-1/4"

67

PT32304067

FOLDING HANDLE 11 X 74, M10-1.5 X 18

7

PT32304007

FENCE

68

PT32304068

HOPPER FUNNEL

8

PT32304008

FENCE SHAFT 305MM

69

PT32304069

BUSHING 22.5ID X 35OD X 15L

9

PT32304009

EXT RETAINING RING 14MM

70

PT32304070

AUGER

10

PT32304010

BALL BEARING 6202RS

71

PT32304071

AUGER SCREW M8-1.25 X 29

11

PT32304011

BLADE 5/8" X 82" 4 TPI

72

PT32304072

REAMER

12

PT32304012

UPPER WHEEL 10"

73

PT32304073

GRINDING PLATE 3/16"

13

PT32304013

INT RETAINING RING 38MM

74

PT32304074

LOCKING COLLAR

14

PT32304014

WHEEL SHAFT M12-1.75 X 43

75

PT32304075

COLLAR GASKET 3.25 X 63.5 X 70

15

PT32304015

WHEEL COVER

76

PT32304076

SAUSAGE STUFFER

16

PT32304016

HEX NUT M10-1.5

77

PT32304077

LOCK WASHER 8MM

17

PT32304017

FLAT WASHER 10MM

78

PT32304078

STAND TOP

18

PT32304018

COMPRESSION SPRING 4 X 18.5 X 42

79

PT32304079

SET SCREW M8-1.25 X 12

19

PT32304019

TENSION PLATE

80

PT32304080

MOTOR PULLEY

20

PT32304020

TRACKING PLATE

81

PT32304081

MOTOR 3/4 HP 120V 1-PH

21

PT32304021

DOWEL PIN 8 X 50

81-1 PT32304081-1 R CAPACITOR 35M 250V 1-1/2 X 2-7/8

22

PT32304022

RETENTION BRACKET

81-2 PT32304081-2 BALL BEARING 6203ZZ

23

PT32304023

ROLLER BRACKET

81-3 PT32304081-3 MOTOR FAN

24

PT32304024

CAP SCREW M6-1 X 10

81-4 PT32304081-4 FAN COVER

25

PT32304025

ROLLER AXLE 10 X 34MM

81-5 PT32304081-5 MOTOR JUNCTION BOX

26

PT32304026

ROLLER 10 X 33MM

81-6 PT32304081-6 STRAIN RELIEF TYPE-3 M18-2.5

27

PT32304027

REAR COVER

82

PT32304082

MOTOR MOUNT

28

PT32304028

HEX NUT M8-1.25

83

PT32304083

UPPER BRACE

29

PT32304029

FLAT WASHER 8MM

84

PT32304084

SWITCH HOUSING

30

PT32304030

CAP SCREW M6-1 X 10

85

PT32304085

ON/OFF SWITCH GAOYOU KJD6 250V

31

PT32304031

LOWER BLADE GUIDE

86

PT32304086

MEAT GRINDER COVER

32

PT32304032

LOWER GUIDE SUPPORT BRACKET

87

PT32304087

PHLP HD SCR M4-.7 X 6

33

PT32304033

BALL BEARING 608-2RS

88

PT32304088

CABLE BOOT 8 X 18MM

34

PT32304034

CAP SCREW M8-1.25 X 25

89

PT32304089

POWER CORD 14G 3W 72" 5-15P

35

PT32304035

SAW BODY

90

PT32304090

LOCK WASHER 4MM

36

PT32304036

SET SCREW M8-1.25 X 16

91

PT32304091

TERMINAL LUG 18AWG

37

PT32304037

HEX NUT M6-1

92

PT32304092

EXT TOOTH WASHER 4MM

38

PT32304038

COLUMN COVER

93

PT32304093

CARRIAGE BOLT M8-1.25 X 16

39

PT32304039

FLAT WASHER 6MM

94

PT32304094

FLAT WASHER 12MM

40

PT32304040

HEX BOLT M8-1.25 X 12

95

PT32304095

SIDE BRACE

41

PT32304041

GUIDE RAIL SUPPORT BRACKET

96

PT32304096

STAND COVER

42

PT32304042

CAP SCREW M4-.7 X 10

97

PT32304097

ROLL PIN 3 X 16

43

PT32304043

BLADE GUIDE RAIL

98

PT32304098

TAP SCREW M2.2 X 12

44

PT32304044

BLADE GUIDE SUPPORT BRACKET

99

PT32304099

STAND LEG

45

PT32304045

SUPPORT BEARING PIN 10 X 34MM

100

PT32304100

STUD-SE M10-1.5 X 104, 54

46

PT32304046

BALL BEARING 6200-2RS

101

PT32304101

TAP SCREW M4.2 X 13

47

PT32304047

EXT RETAINING RING 10MM

102

PT32304102

RUBBER FOOT

48

PT32304048

BLADE GUIDE BRACKET

103

PT32304103

HEX BOLT M6-1 X 20

49

PT32304049

BLADE GUIDE

104

PT32304104

HEX NUT M5-.8

50

PT32304050

BLADE GUARD

105

PT32304105

LOCK WASHER 5MM

51

PT32304051

HEX NUT M12-1.75

106

PT32304106

FLAT WASHER 5MM

52

PT32304052

LOCK WASHER 12MM

107

PT32304107

TABLE SLIDE RAIL (LEFT)

53

PT32304053

BALL BEARING 6005ZZ

108

PT32304108

TABLE SUPPORT BEAM

54

PT32304054

WHEEL PULLEY

109

PT32304109

TABLE SLIDE RAIL (RIGHT)

55

PT32304055

V-BELT A-1000

110

PT32304110

SHAFT HANDLE

56

PT32304056

LOWER WHEEL 10"

111

PT32304111

PULLEY GUARD

57

PT32304057

HEX BOLT M6-1 X 25

112

PT32304112

FLAT WASHER 4MM

58

PT32304058

WHEEL SUPPORT PLATE

113

PT32304113

SWITCH COVER, FRONT

59

PT32304059

BUSHING 19.5ID X 27OD X 30L

114

PT32304114

COVER SEAL

60

PT32304060

BUSHING 19ID X 28.5OD X 30.5L

115

PT32304115

TERMINAL BLOCK PA10-2P

61

PT32304061

HEX BOLT M8-1.25 X 20

116

PT32304116

TAP SCREW M2.9 X 20

-46-

Model T32304 (Mfd. Since 02/21)

Main Parts List

Содержание T32304

Страница 52: ......