Model T28366 (Mfd. Since 04/18)

-33-

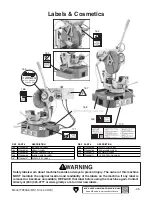

Push the oil can nozzle tip against ball oiler,

and pump oil can twice. If you see sludge and

contaminants coming out of the lubrication area,

continue pumping oil can until the oil runs clear,

and wipe away any excess oil. There are two ball

oilers, located on the front and rear vise bodies

(see

Figure 46).

Note:

For best performance, periodically clean

leadscrew thoroughly with mineral spirits or other

degreaser and then relubricate.

Lube Type ...Model T26685 or ISO 32 Equivalent

Lube Amount ........................................Thin Coat

Lubrication Frequency ........... 8 hrs. of Operation

Proper lubrication of the column hinge-pin allows

for smooth movement of the saw headstock.

If saw headstock movement becomes difficult,

apply a small amount of oil to column joints (see

Figure 47). Move the saw headstock back-and-

forth several times to distribute oil evenly.

Saw Base Pivot

Lube Type ...Model T26685 or ISO 32 Equivalent

Lube Amount ........................................Thin Coat

Lubrication Frequency ........... 8 hrs. of Operation

Proper lubrication around the saw base pivot

allows for smooth rotation when adjusting the

miter angle.

If base pivot movement becomes difficult, apply

a small amount of oil to openings beside the

miter angle gauge (see

Figure 48). Rotate the

base back-and-forth several times to distribute oil

evenly.

Figure 47. Location of column hinge pin.

Oil Access

(1 of 2)

Figure 48. Base pivot oil locations.

Miter

Angle

Gauge

Oil Access

(1 of 2)

Column Hinge Pin

Figure 46. Vise leadscrew lubrication.

Ball Oiler

Vise Leadscrew