-32-

Model T28366 (Mfd. Since 04/18)

Lube Type ... Model T27914 or ISO 68 Equivalent

Lube Amount ............................................

1

⁄

2

-Liter

Check/Add Frequency ..............................Weekly

Change Frequency ..................... Every 6 Months

Items Needed

Qty

Hex Wrench 8mm .............................................. 1

Adjustable Wrench ............................................ 1

Drain Pan ........................................................... 1

Funnel ................................................................ 1

Additional Person .............................................. 1

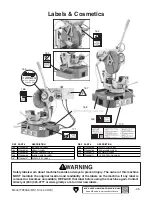

To add/change gearbox oil:

1. DISCONNECT MACHINE FROM POWER!

2. Raise saw to upmost position, and remove

lever arm (see

Figure 45) to access oil fill

hole to allow oil to drain more freely.

3. Place oil drain pan beneath saw gearbox,

and remove oil drain plug, located on bottom

side of gearbox (see

Figure 45).

5. Hold drain pan under drain plug, then tilt saw

gearbox forward, allowing oil to drain out.

6. Have an assistant hold headstock in place,

and replace drain plug.

7. Insert funnel into fill hole. Add approximately

1

⁄

2

-liter of ISO 68 or equivalent oil until oil level

is halfway in sight glass. Wait 10 seconds to

allow oil to settle in sight glass before taking

a reading.

8. Wipe away any excess oil and re-install lever

arm.

Figure 45. Oil fill and drain plug locations.

Sight

Glass

Lubrication

This cold cut saw requires regular lubrication to

maintain smooth movement and ensure long-last-

ing operation.

An essential part of lubrication is cleaning the

components before lubricating them. Clean all

exterior components in this section with mineral

spirits, shop rags, and brushes before lubricating.

This step is critical because grime and chips build

up on lubricated components over time, which

makes them hard to move.

4. Place oil drain pan beneath saw gearbox,

and remove oil drain plug, located on bottom

side of gearbox (see

Figure 45).

Gearbox Oil

Vise Leadscrew

Lube Type ... Model T27914 or ISO 68 Equivalent

Lube Amount ..................................... 1–2 Pumps

Lubrication Frequency ........... 8 hrs. of Operation

Proper lubrication of the vise leadscrew (see

Figure 46) is done with a pump-type oil can that

has a tip wide enough to seal the ball oil inlet. We

do not recommend using metal needle or lance-

type tips, as they can push the ball too far into the

oiler, break the spring seat, and lodge the ball in

the oil galley.

Oil Drain

Plug

Oil

Fill Hole