Model G0833P (Mfd. Since 06/17)

-47-

Resawing Operations

The table saw motor is pushed to its limits when

resawing. If the motor starts to bog down, slow

down your feed rate. Motor overloading and blade

wear can be reduced by using a ripping blade.

Ripping blades are designed to clear the sawdust

quickly.

Components Needed for Resawing:

Zero-Clearance Insert ........................................1

Ripping Blade 10" ...............................................1

Clamps ...............................................................2

Shop-Made Auxiliary Fence ...............................1

Shop-Made Resaw Barrier .................................1

To perform resawing operations:

1. DISCONNECT MACHINE FROM POWER!

2. Remove standard table insert and blade

guard assembly.

3. Install a ripping blade, install riving knife,

lower blade below table surface, then install

zero-clearance table insert.

You may experience kickback during this

procedure. Stand to the side of the blade

and wear safety glasses and a full face

shield to prevent injury when resawing.

4. Attach auxiliary fence and set it to desired

width.

Note: When determining correct width,

don't forget to account for blade kerf and

inaccuracy of fence scale while auxiliary

fence is installed.

5. Place workpiece against auxiliary fence and

slide resaw barrier against workpiece, as

shown in

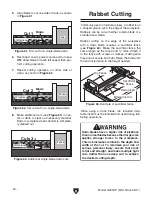

Figure 72. Now clamp resaw bar-

rier to top of table saw at both ends.

Auxiliary

Fence

Fence

Resaw

Barrier

1

/

8

" Connection

Workpiece

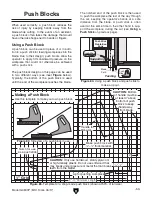

Figure 73. Ideal completed resaw cut.

6. Lower blade completely below table-top, and

slide workpiece over blade to make sure it

moves smoothly and fits between resaw bar-

rier and fence.

7. Raise blade approximately 1 inch, or close to

half the height of workpiece (see

Figure 73),

whichever is less.

Figure 72. Ideal resaw workpiece setup.

Auxiliary

Fence

Fence

Resaw

Barrier

Workpiece

(Front View)

Содержание Polar Bear G0833P

Страница 92: ......