Model G0701 (Mfd. Since 9/17)

-19-

Initial Blade Tracking

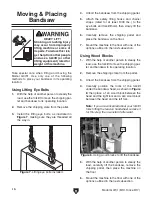

Serious personal injury

may occur if the machine

accidentally starts dur-

ing this procedure.

Disconnect the machine

from power and keep

your hands away from

the blade when adjusting

blade tracking.

Blade tracking is affected by the tilt of the upper

wheel (known as center tracking) and the align-

ment of both wheels (known as coplanar tracking).

The wheels on this bandsaw were aligned at the

factory, so center tracking is the only adjustment

that needs to be performed when the saw is new

(refer to the

Aligning Wheels subsection on Page

64 for detailed instructions on coplanar tracking).

To center track the blade:

1. DISCONNECT MACHINE FROM POWER!

2. Adjust the upper and lower blade guides

away from the blade (refer to

Adjusting

Blade Guide Bearings on Page 28 for

detailed instructions).

Note:

When adjusting the blade tracking, the

blade must have a reasonable amount of ten-

sion to simulate operating conditions. After

the

Test Run is successfully completed, you

will perform a thorough version of the follow-

ing steps to correctly tension the blade.

3. Move the blade tension quick release lever all

the way right (as viewed from the rear of the

machine) to apply tension to the blade (see

Figure 14).

Tension

Handwheel

Figure 14. Blade tension controls.

Quick

Release

Lever

Tension

Scale

4. Use the tension handwheel to bring the

pointer on the tension scale to the appropri-

ate mark for the blade width.

Note: Changes in the blade tension may change

the blade tracking. For best performance, regular-

ly check and maintain the proper blade tracking.

The cast iron wheel spokes may have sharp

edges and the blade teeth may extend

beyond the edge of the wheel, creating

a laceration hazard. Wear heavy leather

gloves and be careful when turning the

wheels by hand.

Adjustment Overview

The bandsaw is one of the most versatile wood-

working machines. However, it has multiple com-

ponents that must be properly adjusted for the

best cutting results.

For practical and safety reasons, some adjust-

ments and test operations must be performed

before performing other necessary adjustments.

Below is an overview of the order in which they

should be performed:

•

Initial Blade Tracking

•

Adjusting Positive Stop

•

Test Run

•

Tensioning Blade

•

Aligning Blade Support Bearings

•

Adjusting Blade Guide Bearings

•

Aligning Table

•

Aligning Fence

•

Calibrating Miter Guage

•

Calibrating Fence Pointer