-14-

Model G0678 (Mfd. Since 06/15)

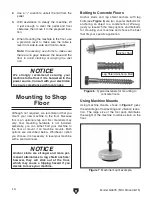

Although not required, we recommend that you

mount your new machine to the floor. Because

this is an optional step and floor materials may

vary, floor mounting hardware is not included.

Generally, you can either bolt your machine to

the floor or mount it on machine mounts. Both

options are described below. Whichever option

you choose, it is necessary to level your machine

with a precision level.

Mounting to Shop

Floor

NOTICE

Anchor studs are stronger and more per-

manent alternatives to lag shield anchors;

however, they will stick out of the floor,

which may cause a tripping hazard if you

decide to move your machine.

Figure 7. Machine mount example.

Using Machine Mounts

Using machine mounts, shown in

Figure 7, gives

the advantage of fast leveling and vibration reduc-

tion. The large size of the foot pads distributes

the weight of the machine to reduce strain on the

floor.

NOTICE

We strongly recommend securing your

machine to the floor if it is hardwired to the

power source. Consult with your electrician

to ensure compliance with local codes.

2. Use a

1

⁄

2

" wrench to unbolt the mill from the

pallet.

3. With assistance to steady the machine, lift

it just enough to clear the pallet and floor

obstacles, then move it to the prepared loca-

tion.

4. When mounting the machine to the floor, use

a precision level to make sure the table is

level from side-to-side and front-to-back.

Note: If necessary, use shims to make sure

there are no gaps between the base and the

floor to avoid cracking or warping the cast

iron.

Bolting to Concrete Floors

Anchor studs and lag shield anchors with lag

bolts (see

Figure 6) are two popular methods for

anchoring an object to a concrete floor. We sug-

gest you research the many options and methods

for mounting your machine and choose the best

that fits your specific application.

Figure 6. Typical fasteners for mounting to

concrete floors.

Anchor Stud

Lag Shield Anchor & Bolt