-28-

Model G0678 (Mfd. Since 06/15)

Leadscrews

Lubricant

Frequency

Qty

NLGI #2 Grease

Every

40 Hours

of Operation

Thin

Coat

Use a shop rag and mineral spirits to clean away

debris and grime from the longitudinal, cross, and

elevation leadscrews and leadscrew nuts. Apply

a thin coat of lubricant to the leadscrews, then

move the table through the full range of move-

ment for each leadscrew to distribute the grease

(see

Figures 37–38).

Figure 38. Cross and vertical leadscrews.

Cross

Leadscrew

Vertical

Leadscrew

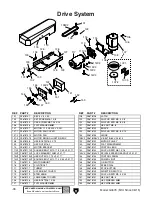

V-Belt Tensioning

Power is transferred from the motor to the spindle

with a V-belt. With normal use, this belt will gradu-

ally stretch over time. When it does, perform the

following procedures to re-tension it.

Tools Needed

Qty

Wrench 24mm ................................................... 1

To tension the V-belt:

1. DISCONNECT THE MILL FROM POWER!

2. Lift the V-belt cover, then loosen the adjust-

ment bolt jam nut near the motor (see

Figure 39).

3. Rotate the adjustment bolt until the V-belt has

approximately 1" of deflection when moder-

ate pressure is applied midway between the

pulleys (see

Figure 40), then re-tighten the

jam nut and close the V-belt cover.

Approximately 1"

Deflection

Figure 40. Checking for belt deflection.

Figure 39. V-belt tension adjustment bolt.

V-Belt

Adjustment

Bolt & Jam

Nut

Figure 37. Longitudinal leadscrew.

Longitudinal

Leadscrew