-10-

G0620 Main Control Panel

Memory Functions

The Model G0620 controller can store up to 29

different cut settings. Each cut setting will save

positions for the blade height, blade angle, and rip

fence cutting width.

Saving Cut Settings

1.

Move the blade height, blade angle, and rip

fence to the positions that you want to save.

(Refer to

Combining Adjustment Entries

for

more details on how to enter all these

dimensions at one time.)

For Example:

Set the blade height to 2.25",

the blade angle 22.5, and the rip fence posi-

tion 18.25", as shown in

Figure 15

.

2.

Press and hold the memory set

key until

"S" displays in the blade speed display and

the other numbers flash, as shown in

Figure

16

.

����

����

�����

����

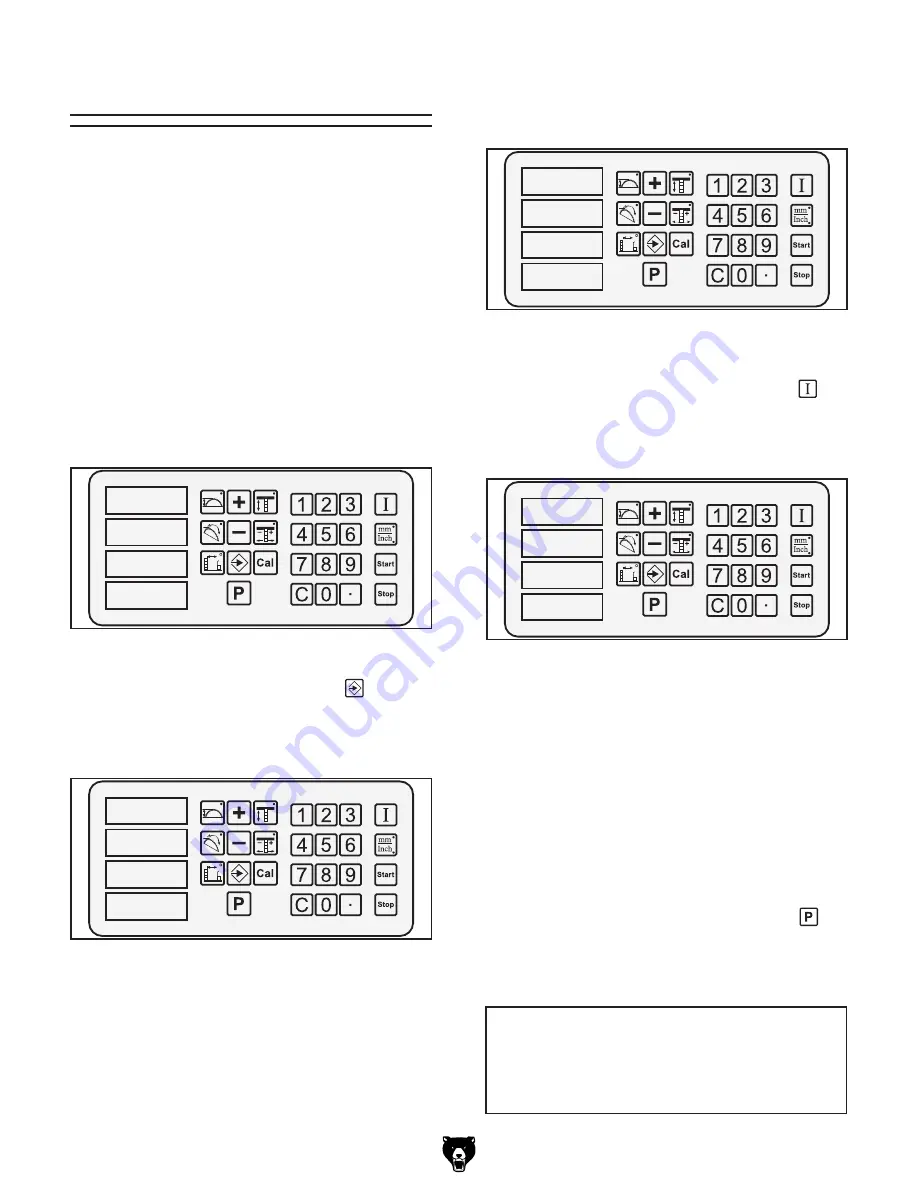

Figure 15.

Example dimensions entered.

����

����

�����

�

�����

��

Figure 16.

"S" displayed on control panel to

indicate system is ready to save settings.

3.

Type in a number between 1 and 29 to repre-

sent this saved setting.

����

����

�����

�

�����

��

Figure 17.

The number 22 programmed to save

the currently shown dimensions.

4.

Press and hold the input confirmation

key

until the display stops flashing. The screen

will return to the normal view, as shown in

Figure 18

.

����

����

�����

����

Figure 18.

Screen returned to normal view.

Recalling Pre-Saved Settings

To demonstrate how saved settings are recalled,

move the components to the following positions

before beginning this procedure: blade height to

0.00, blade tilt to 0.0, rip fence position to 10.00.

(Refer to

Combining Adjustment Entries for

more details on how to enter all these dimensions

at one time.)

To recall a saved setting:

1.

Press and hold the pre-saved memory key

until "P" displays in the blade speed display

and the memory numbers flash, as shown in

Figure 19

.

NOTICE

If the numerical input exceeds the compo-

nent limit, it will not completely move, and

may return an "OL" on the display.

Use the number 22 to save the example

dimensions from

Step 1

. The display should

look like

Figure 17

.