19

5.

4.

The spindle gibs ensure there is no play in the

spindle that could cause it to wobble.

To adjust the spindle gibs:

1.

DISCONNECT SHAPER FROM POWER

SOURCE!

2.

Elevate the spindle to its maximum 3"

height.

3.

If there is movement, adjust the gib against

the elevation housing, using the adjustment

screws at the top and bottom of the elevation

housing.

Figure 17

shows the two upper gib

adjustment screws and locknuts. One of the

two lower adjustment screws is also visible in

the photo.

Loosen the four 12mm locknuts and remove

the slack between the elevation housing

and spindle cartridge slide by tightening the

four

5

⁄

16

" setscrews with a 4mm hex wrench.

Alternate between the upper and lower

adjustments to ensure consistent tightness.

Failure to do so may cause disappointing

results. DO NOT over-tighten the gib. Over-

tightening will restrict spindle movement.

Loosen the spindle assembly lock knob and

raise or lower the spindle to check for free

movement.

Since there is an unbalanced weight distribu-

tion on the cartridge slide, you may have to

perform a number of adjustments before you

find the ideal location. Don’t get discouraged;

it may take a few tries to get it right.

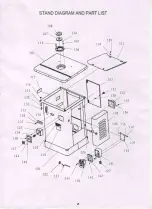

Gib Adjustments

Figure 17.

Gib adjustment screws.

Upper Gib

Adj.

Screws

Lower

Gib Adj.

Screw

Содержание G1026

Страница 1: ...2 HP SPINDLE MOULDER INSTRUCTION MANUAL ...

Страница 2: ... 1 ...

Страница 4: ... SECTION 1 SAFETY 3 ...

Страница 5: ... 4 ...

Страница 9: ...Hardware Recognition Chart 8 ...

Страница 22: ...21 ...

Страница 23: ...22 ...

Страница 24: ...23 ...

Страница 25: ...24 ...

Страница 26: ...25 ...

Страница 27: ...26 ...

Страница 28: ...27 ...

Страница 29: ...28 ...