Page 33

SLT 5.0 Level and Flow Monitor

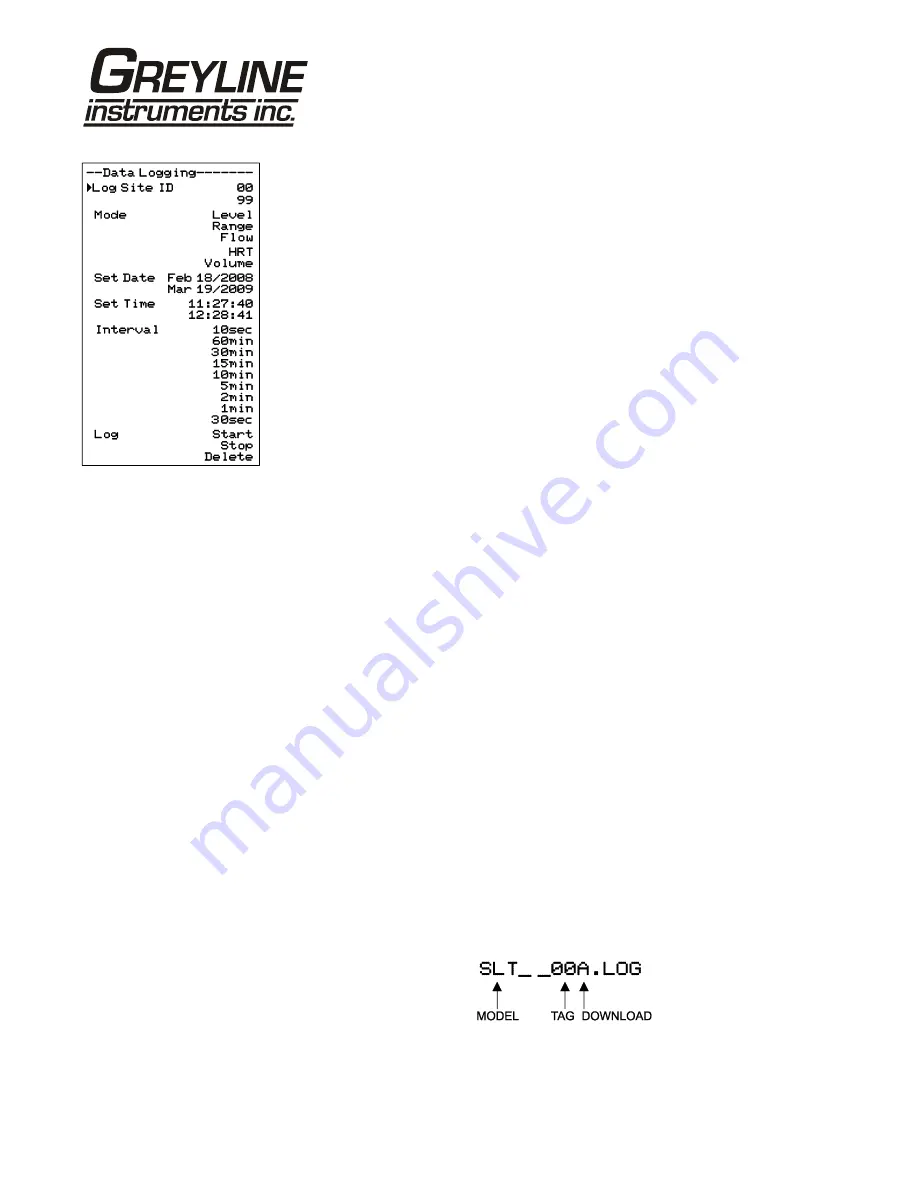

DATA LOGGING (Optional)

Setup

Select Data Logging from Menu Selections.

Log Site ID

Enter a number from

00

to

99

. The site ID will

become part of the downloaded file name to help

distinguish downloads from different instruments. Press

to store the setting.

Mode

Select

Level

,

Range

,

Flow

,

HRT

and

Volume

.

Flow

(e.g. USGPM or l/sec). Press

to store the setting.

Set Date

Press

or

to scroll and select Month, Day and Year.

Press

to store the setting.

Set Time

Press

or

to select the current time in Hours, Minutes

and Seconds. Press

to store the setting.

Interval

Press

or

to select the logging interval. Flow rate

reading will be stored at each time interval. Press

to

store the setting.

Note: Press

to Log

and

or

to Delete and

to

delete the log file. Press

and

or

to Start and

to

restart the logger.

Log

Stop

,

Start

or

Delete

the log file. Delete old file and

start a new log to apply any changes that have been made

to the

Log Site ID

,

Mode

or

Interval

.

RETRIEVE LOG FILE

Plug a USB Flash Memory Drive (not supplied by Greyline) into the USB output

cable from the instrument. The instrument display will show the message

Downloading until the log file is transferred to the memory card and then display

Completed. The USB flash drive may be removed.

Download file names will appear in this format:

Tag is set according to the Log Site ID entered in the instrument Data Logging

menu.

Download letter will be A for the first download from an instrument. B for the

second, then C etc. At the letter Z a - character will appear indicating that the

Содержание SLT 5.0

Страница 2: ...Note This page has been left blank intentionally ...

Страница 5: ...Page 5 SLT 5 0 Level and Flow Monitor CONNECTIONS ...

Страница 7: ...Page 7 SLT 5 0 Level and Flow Monitor CALIBRATION MENU ...

Страница 14: ...Page 14 SLT 5 0 Level and Flow Monitor CHANNEL SETUP ...

Страница 20: ...Page 20 SLT 5 0 Level and Flow Monitor SENSOR MOUNTING METHODS ...