4. Cut the right wing tip loose from the wing and use

a Dremel Moto Tool to hollow out the wing tip. (This will

help to compensate for the weight of the engine head and

muffler).

5. Now securely glue the right wing tip in place.

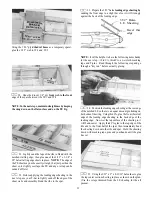

Cut 2" off Aileron stock

and glue permanently to TE

6. Cut 2" off one end of the tapered ailerons and glue

the 2" pieces permanently to the trailing edge as shown in the

sketch. This moves the aileron away from the turbulence

caused by the tip vortex. Make sure you carefully line up this

piece with the top and bottom surfaces of the wing.

to make room for the torque rod bearings. Trial fit the ailerons

onto the torque rods and cut or file as necessary until they fit.

6. Lay the ailerons on the plan and mark the hinge

locations on the ailerons. Use two hinges near the tips. Place

the ailerons against the wing TE and transfer the marks over

to the wing.

7. Cut the hinge slots in the ailerons and wing TE using

an Xacto knife or hinge slotting tool.

8. IMPORTANT! Condition or "break-in" the hinges

INSTALL AILERONS

NOTE: Do not glue the aileron hinges until after your model

has been covered.

by folding them back and forth several times,

"V"-shape as shown on the wing rib detail drawing.

9. Sand the leading edge of the ailerons to the same

1. Draw an accurate centerline along the LE of the

tapered balsa ailerons and the wing TE,

2. Check the length of your ailerons against the actual

10. Insert the hinges into the slots and trial fit the

ailerons in place on the wing. Do not glue the hinges until

after you have covered the wing.

aileron openings and trim the ailerons as necessary. You

should provide approximately 1/16" gap at each end of the

ailerons.

There should be no hinge gap!

11. Now is a good lime to finish the wing tips. Tape the

ailerons on in the neutral position, and sand the wing tips to

blend with the ailerons.

INSTALL WING DOWELS

3. Lay the ailerons in place in the openings, with the

torque rods resting on lop of the ailerons. Mark the torque

rod locations on the top of the ailerons.

4. Drill a 7/64" hole in the ailerons at the torque rod

locations, starting at the leading edge centerline and drilling

straight in to the proper depth. (The hole is drilled slightly

oversize to allow for positioning, and to create a hard epoxy

"sleeve" around the wire).

5. Use the sharpened 1/8" diameter brass tube to cut a

groove in the leading edge of the ailerons to accept the

torque rods. Cut these grooves a little larger at the beginning,

1. Mark a horizontal centerline on the flat which you

sanded on the wing LE. Also mark a vertical centerlineon the

die-cut 1/8" ply former F-2A (the Wing Dowel Plate).

16