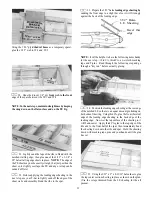

File end to

wedge shape

pieces in place with epoxy. HINT: Use masking tape to hold

these pieces to the wing TE, to aid in correct positioning.

SAND "FLATS" ON LE AND TE

2. Roughen the surface of the plastic bearing tubes

with 100-grit sandpaper.

3. Clean the torque rods and bearing tubes with alco-

1. Study the wing plan near the wing centerline. Note

that the center portion of the LE and TE must be sanded flat.

hol.

4. Find the two grooved, tapered balsa center trailing

edge pieces. Lay them on the plan, mark and cut them off to

match the plan for length and angle at the centerline.

2. Sand approximately 5/32" into the LE at the center-

line, and approximately 3/32" into the TE at the centerline.

(The flats will end up approximately 4-1/2" wide at the LE,

and 2" wide at the TE).

5. Trial fit the torque rods into the center TE pieces.

Determine from the plan where to cut the clearance notches,

which will permit the torque rod horns to travel freely. Also

cut small clearance notches in the wing TE. Note: The

torque rod horns must exit the TOP of the wing!

FIBERGLASS THE CENTER SECTION

6. Slide the plastic bearings toward the threaded end of

the torque rods, then use a toothpick to apply a small amount

of petroleum jelly to the ends of the plastic tubes (to help

prevent glue from getting inside and locking up the torque

rods).

7. Use 5-minute epoxy or thick CA to glue the plastic

bearing tubes into the grooves in the center TE pieces. Wipe

off any excess glue and allow it to harden.

NOTE; Because of the high stresses in the center of this

wing, Fiberglass reinforcement is REQUIRED. Please do

not omit this important section!

NOTE: If you have previous experience with applying

fiberglass, feel free to use your favorite method, providing

that it results in a strong bond between the glass cloth and the

wood. If this is your first time, we offer the following

suggested method, which is the fastest and easiest we have

seen.

8. Trial fit the trailing edge / torque rod assemblies

onto the wing trailing edge. Sand the center trailing edge

pieces slightly where they join, for a good fit. Glue these

1. Make location marks for the fiberglass reinforce-

ment cloth, 2" each way from the wing centerline.

14