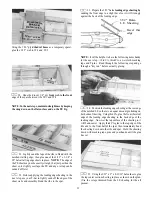

12. Find the 1/4" ply wing hold-down block and trial fit

15. Use 30-minute or 5-minute epoxy to securely glue

it into the notches in the fuse side doublers, sanding as

necessary for a good fit. Glue the hold-down block in place

securely, using 30-minutc epoxy, then cut pieces of 1/4"

balsa triangle and glue them in place above and below the

hold-down block. Sand the triangles flush with the wing

saddle.

F-l to the fuse sides, holding with clamps or tape until the

glue has firmly set. NOTE: Before the glue sets. double

check to make sure F-1 is properly aligned with the top and

bottom edges of the fuselage, and fully back against the

firewall spacers. After the glue has fully hardened, sand off

the front of the fuse sides flush with the front of F-l.

13. The 1/4" ply firewall (F-l) location and size will

vary, depending on which engine you install. The location

has been set by the firewall spacers. The firewall supplied in

your kit is the correct size if you are installing a .91 4-stroke

engine; however, if you are installing a smaller engine, such

as a .70 4-stroke or a .61 2-stroke, you will have to cut the

firewall down to the correct size. The fuse plan shows the

firewall sizes and engine mounting required for the three

locations. Cut the firewall to size and sand the sides and

bottom at an angle to match the fuse. Trial fit to make sure it

will fit correctly before proceeding to the next step.

14. Before installing the firewall (F-l), you may drill

F-l for your engine mountand install the 6-32 blind nuts. You

may cut out the appropriate F-l drawing from the plans, tape

it to F-l and use it as a guide for drilling the four 5/32" holes.

If you will be using a mount not shown on the plans you'll

have to determine the correct mounting position. Note that

the mount should not be positioned on the vertical and

horizontal centerlines of F-1, but should be offset slightly

above the centerline and slightly toward the left side. (When

taking measurements off the plan, keep in mind that the plan

shows the bottom view of the airplane). Drill the holes and

install the blind nuts on the back ofF-1, pressing them in with

a pliers or a vise.

6-32

Blind Nut

21

#6 x 1" Screw

16. Cut pieces of 3/8" balsa triangle to fit around the aft

edges of F-1, and glue them in place.

DRILL ENGINE MOUNT

(Great Planes MM60L mount)

1. Place the engine pointing straight ahead on the

mount and mark the mounting hole locations on the mount.

At the marked locations, accurately drill 7/64" (or #36) holes.

NOTE: If you have access to a drill press, use it for drilling

these holes to insure that they are drilled vertically.

2. Now you may use one of the following methods to

attach your engine to the mount:

Method 1: Screw the #6 x 1" sheet metal screws

(provided in the kit) through the engine mounting flange and

into the mount. When first installing these screws, put a drop

of oil into each screw hole.