NOTE: If you are installing retracts, disregard steps 26

through 29.

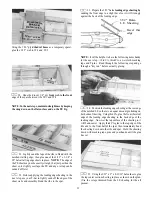

26. Remove the wing from the building board and

trial fit the long grooved hardwood LG block into the notches

in ribs W-2, W-3 and W-4 (see the landing gear detail drawing

on the wing plan for proper positioning). File the notches if

necessary for a good fit. Now use epoxy to securely glue the

block in place.

27. Epoxy the 7/16" x 5/8" x 7/8" hardwood block to

Photo of finished wing with retract mechanism removed.

NOTE: If you will be installing retracts, now is the time to

glue in the 1/16" ply die-cut rib doublers to the front portion

of ribs W-3 and W-4. (Make sure the front rib doublers are on

the outboard side of W-3 and the inboard side of W-4). This

is also the time to install the 1/4" x 13/16" x 2-11/16" ply

retract mounting rails on the bottom of the wing, in the

location shown on the plan. Lock and strengthen the joints

between the 1/4" ply rails and the 1/16" ply rib doublers by

gluing 1/4" balsa triangle stock to these joints. You should

also now do some planning and trial fitting of the retract and

pushrod, customizing the installation as necessary [to|

accommodate your retracts. Installing retracts requires

careful planning and a lot of trial fitting: therefore, you should

take the time now to plan out your installation.

the LG block and to the 1/16" ply doubler on rib W-2, as

shown on the plan and in the photo, then epoxy the small

hardwood block to the other end of the LG block and to the

1/16" ply doubler on rib W-4.

31. With the wing upside down, again use the TE jig

to support the TE. Then install the bottom TE sheeting, LE

sheeting and Center Section sheeting, cutting and fitting the

sheeting around the LG block as necessary. IMPORTANT

NOTE: To insure a straight wing, you must pin or weight

the TE securely down on the TE jig while the bottom

sheeting is glued in place!

block and the 7/8" block. Line up the drill so you are drilling

straight down through the middle of the 7/8" block.

28. Drill a 5/32" hole down through the grooved LG

29. Trial fit the 5/32" diameter main landing gear

32. From the 3/32" x 3/8" x 30" balsa sticks, cut and

wire into the landing gear block at this time. Cut or file the

groove and hole in the landing gear block as necessary for a

good fit

glue cap strips to all exposed ribs, top and bottom. HINT:

For easier positioning of the cap strips, first mark the location

of each rib on the LE and TE sheeting.

30. Using a razor saw and a sanding block, carefully

cut off and sand all excess sheeting, spars, LE and TE even

with W-l and W-ll.

33. Trim the sheeting flush with ribs W-l and W-ll

and sand the entire wing panel smooth. Sand the leading edge

to smoothly blend with the LE sheeting (see the note on the

following page).

12