D 17. Screw the nylon clevises back on the rear ends

of the pushrods. Pry the clevises open with a screw-

driver and hook them up to the outer holes in the

nylon elevator and rudder horns. Twist the pushrods

slightly, so the rods come out of the fuse side slots

without binding.

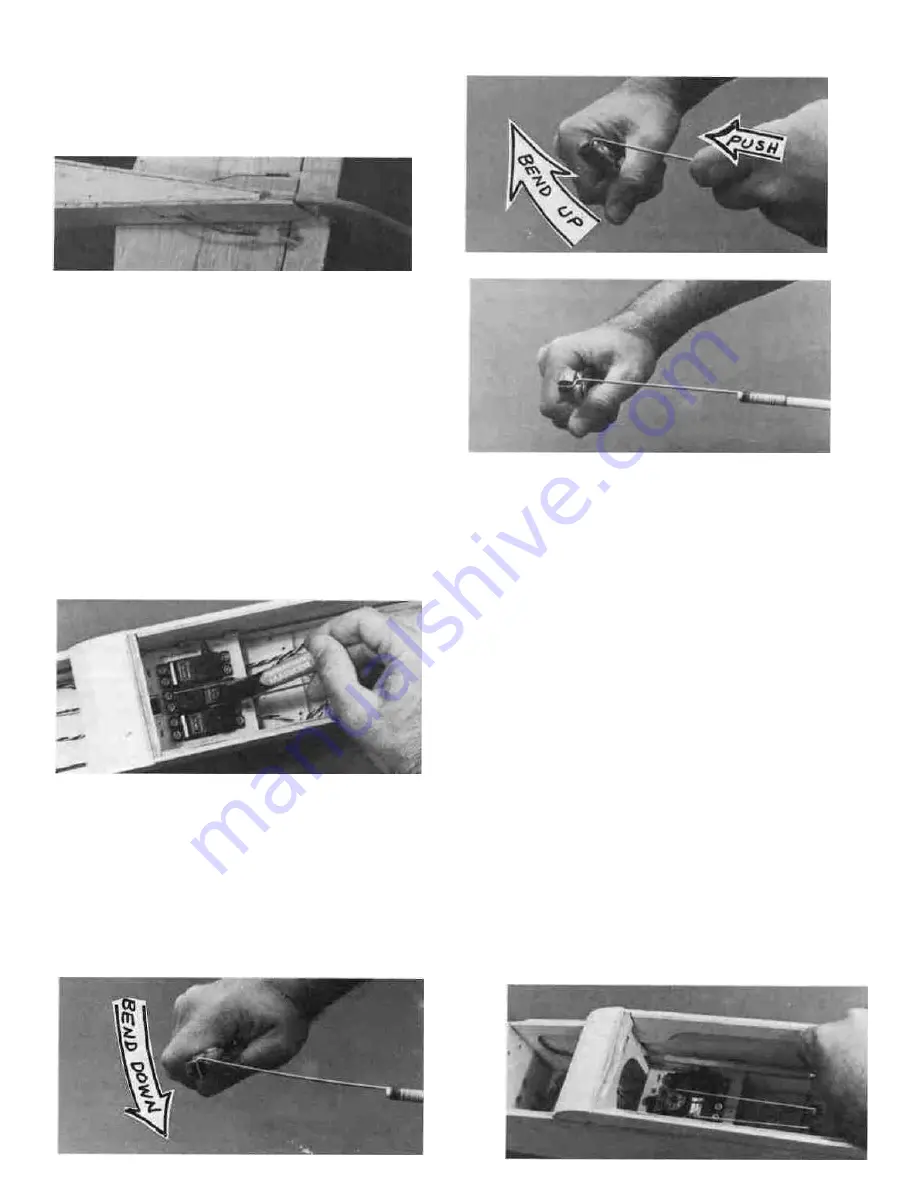

B-Bend up with pliers.

C-Finish Z-bend.

D 18. Temporarily hook up the receiver, battery

pack, switch and servos. Read the instruction man-

ual for your radio to learn how to do this.

D 19. Center the "trim tabs" on your radio transmit-

ter for the elevator, aileron and rudder controls. The

trim tab for the throttle should be pushed all the

way forward.

D 20. Turn on the transmitter and receiver so the

servos rotate to their normal "centered" positions.

Now turn off the receiver and transmitter (in that

order).

D 21. With the rudder centered (straight with the

fin) lay the front part of the rudder pushrod across

the hole in the servo wheel where it will attach. Using

an indelible marker, make a small mark on the push-

rod at the hole location.

D 22. Center the elevator and mark the pushrod

where it goes across the hole in the elevator servo

wheel.

L_] 23. Remove the elevator and rudder pushrods from

the fuselage and make "Z"-bends in the pushrods at

the marks you just made. Here's how...

A-Bend down with pliers.

D 24. Now you may re-install the pushrods and in-

sert the Z-bends into the servo wheels. Note: To do

this you must remove the servo wheel from the servo,

drill out the hole in the servo wheel to 5/64" diameter,

work the Z- bend into the hole, and replace the servo

wheel on the servo.

D 25. Turn the radio on, and check the movement

of the elevator and rudder. To re-center the elevator

and rudder, turn the clevis on the rear end of the

pushrod.

D 26. From die-cutting scrap, cut two pieces of 1/8"

plywood 1/4" wide and 2-3/4" long. Glue these "push-

rod braces" to the front of F-4, above and below the

pushrod dowels, as shown in the drawing of F-4 on

the bottom of the fuse plan.

D 27. To provide adequate movement to move the

throttle from full power to idle, you will probably

have to use a longer servo arm than the small wheel

which is standard on the servo. Take one of the 4-arm

servo arms and cut off three of the arms.

D 28. With the long arm attached to the throttle

servo, as shown on the fuse plan top view, lay a pencil

across the top of the arm and make a mark on the

back of F-2. Also make a mark for the nose gear

pushrod hole. Note: Also see the drawing of F-2 near

the bottom of the plan.

27