❏

14. Make any additional needed cut outs in the cowl for

the muffler, glow driver, needle valve, etc.

❏

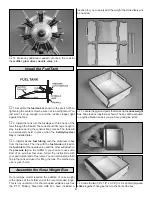

1. Assemble the fuel tank as shown in the sketch. When

tightening the center screw be sure not to overtighten it. You

just want it snug enough to pull the rubber stopper tight

against the tank.

❏

2. Install the tank into the fuselage with the neck of the

tank through the firewall. The tank should fit snug enough to

stay in place during the construction process. The tank will

be permanently held in place when the battery/receiver

tray is installed later.

❏

3. Install silicone fuel tubing onto the aluminum tubes

from the fuel tank. The line with the fuel clunk will feed to

the fuel inlet at the needle valve and the other will attach to

the pressure tap on the muffler. If you choose to use some

kind of an external fuel valve, follow the instructions with

your particular brand of fuel valve. You can also install a third

line to the tank and use it for filling the tank. The method you

use is your choice.

Our prototype model required the addition of nose weight

with engines at the bottom end of the recommended range.

This is not uncommon for short-coupled airplanes such as

the PT-17 Military Stearman ARF. We have included a

location for you to easily add the weight that most likely will

be needed.

❏

1. Locate the plywood parts that make up the nose weight

box. Glue the box together as shown. The box will be exposed

to engine vibration so be sure you have good glue joints.

❏

2. Glue the two 1/8" x 1/4" x 3-1/4" [3 x 6.4 x 83mm] plywood

sticks together. Then glue them to the front of the box.

Assemble the Nose Weight Box

Install the Fuel Tank

21