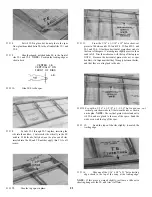

Note: Photo shows uncovered structure.

D 7. Install the rudder cables. Pass the cables through

the crimp fittings as shown on the plan, and squeeze the fit-

tings securely with a pliers. NOTE: When attempting to

run the cables from the rudder horns to the servos, it will help

to glue the end of the cable to a long piece of small diameter

music wire, then pull the cable through with the wire. Install

the EZ Connectors onto the rudder servo arms, and pass the

rudder cables through the EZ Connectors. Pull the cables

snug*, and secure them inside the EZ Connectors with 4-40

set screws, tightened down onto the cables. Pull on the

cables to check for slippage.

4-40 ALLEN

SETSCREW

•It is not necessary (or desireable) to pull the cables ex-

tremely tight, as this will cause excess friction and servo

wear. Just make sure all the slack has been taken up. Verify

this by grasping the rudder and moving it from side-to-side.

There must be no free-play in the rudder.

D 8. Apply 1/16" x 1/4" foam wing seating tape on

both sides of the wing saddle area to protect the wing.

D 9. Run the receiver antenna along the bottom inside

of the fuselage, and let the excess antenna length trail be-

hind.

D 10. Install the 6-32 x 1/4" set screw in the aluminum

prop hub, then attach the prop hub to the motor shaft.

Tighten the set screw firmly down onto the "flat" on the

motor shaft using the hex key supplied. NOTE: When

installing the prop hub, it may be helpful to file the hex key

shorter, making it easier to use without touching the nose

block.

FILE OFF

THIS PORTION

6-32 SET SCREW

D 11. Slide the propeller onto the prop hub, and secure

it with the aluminum spinner nut and the 6-32 socket head

cap screw. Tighten the cap screw with the hex key supplied,

but do not overtighten! ("Finger-Tight" not "Wrench-

Tight" is a good rule of thumb).

6-32 SOCKET HEAD

CAP SCREW

NOTE: Although not included in this kit, you may use a 1-1/4"

plastic spinner for a sleeker appearance. If you use a spinner, you

may have to use a different length 6-32 socket head cap screw,

because of the thickness of the spinner backplate. CAUTION: If

you use a Goldberg Snap-On spinner, you must modify the snap lugs

so they insert more easily without damaging the motor.

D 12. (Optional) Install the main landing gear, using

the nylon straps and #2 x 3/8" screws provided. Drill the

wheel hubs if necessary to fit the main gear. Secure the

wheels with 1/8 "wheel collars. NOTE: A small drop of oil

on each axle will help the wheels turn freely.

D 13. (Optional) Roughen the 1/16" wire tail skid with

sandpaper, and clean it with alcohol. Glue the tail skid into

the hole you previously drilled, using CA glue or epoxy.

BALANCE YOUR MODEL

NOTE: This section If very important and must not be omitted!

D 1. With the wing attached to the fuselage, all parts of

the model installed. Including the 7-cell motor battery,

gently turn the model upside down.

D 2. Carefully measure 3.3/4" Inches (3.75") back

from the LE of the wing along both sides of the fuselage and

mark the location of the recommended balance point. Now

turn the model right side up.

D 3. Lift the model with your index fingers at the marks

you made at the recommended balance point (or for more

precision you may lift with the eraser end of two pencils).

If the tail drops when you lift, the model is "tail heavy" and

you must add weight to the nose to balance. If the nose drops.

it is "nose heavy" and you must add weight to the tail to

balance.

(See photo at the top of the next column.)

31

Содержание Electro Streak

Страница 37: ...37 Use this three view drawing for planning your trim scheme...

Страница 38: ...NOTES 38...