Instruction Manual GRAF SINGLE LUB 2 / Version 4.0

–

05.2020

22

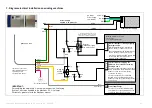

7. Diagram electrical installation on winding machines

If present, connect the

other Single Lub 2 the

same way as it is

shown for this device.

A1 (+)

A2 (-)

12

11

14

green

brown

white

yellow

grey

white

yellow

grey

Relay R1

(Running/Stopping

the Single Lub 2)

0VDC

Relay R2

24VDC

(SPCO)

graf

Single Lub 2

+24VDC

0VDC

green

brown

+24VDC

Power Supply

24VDC / 1,2A per device

IMPORTANT:

For enabling the Single Lub 2, on some machines

the “Graf oiling

System”

, has to be enabled in the Machines P.L.C. settings.

For details, please refer to the Machines manual.

230V~ (L)

0V~ (N)

(PE)

L

N

PE

V-

V+

Separate Power Supply

AC Mains

Power Supply

from Machine

Winding machine electronic

control unit

(one single spindle only)

A1

A2

Interface Output for running/stopping

the Single Lub 2.

Energizing the Relay R1 will start the

device. (Relay contact 11-14 closes)

De-energizing the Relay R1 will stop the

device. (Relay contact 11-14 opens)

User proper Relais operating voltage and

current type (DC/AC) to meet the

interface output capabilities.

OK

fault

Interface Input for stopping the

spindle in case of fault detected by

the Single Lub 2.

In case of normal operation of the Single

Lub 2, Relay R2 is energized and contact

between I1 and I2 is closed (Relay

contact 11-14 closes)

In case of a fault has been detected,

Relay R2 is de-energized and contact

between I1 and I2 is open (Relay contact

11-14 opens)

I1

I2

A3

Interface Output for Lube speed

control (Optionally)

In case of non-constant winding speed,

this speed clock signal (0V-24V p-p) can

control the Lube rate if necessary

(optionally)

A1 (+)

A2 (-)

12

11

14

*

run

stop

*

Connect Protection Diode only for

DC-driven Relays in order to protect

the machine interface output stage.

Protective earthing

pink