Pressure Relief Procedure

3A2247A

9

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

1.

Set pump valve OFF.

2.

Turn gas engine or electric motor OFF.

3.

Unplug power cord.

4.

Turn pressure to lowest setting. Trigger gun into

pail to relieve pressure.

5.

Turn prime valve down.

If after following these steps you suspect the spray tip or

hose is still clogged or that pressure has not been fully

relieved,

very slowly

loosen tip guard retaining nut or

hose end coupling to relieve pressure gradually. Then

loosen completely.

Maintenance

NOTE:

For detailed engine maintenance and specifica-

tions, see separate Honda owner’s engine manual (sup-

plied).

DAILY:

Check hydraulic oil level and fill as necessary.

DAILY:

Check gas engine oil level and fill as necessary.

DAILY:

Check hose for wear and damage.

DAILY:

Check gun safety for proper operation.

DAILY:

Check pressure drain valve for proper operation.

DAILY:

Check that displacement pump is tight.

DAILY:

Check level of Throat Seal Liquid (TSL) in dis-

placement pump packing nut. Fill nut, if necessary. Keep

TSL in nut to help prevent fluid buildup on piston rod and

premature wear of packings and pump corrosion.

WEEKLY/DAILY:

Remove any debris or media from

hydraulic rod.

AFTER EACH 100 HOURS OF OPERATION:

Change

engine oil (see Honda engine owner’s manual for correct

oil viscosity).

SEMI-ANNUALLY:

Check belt wear, replace if necessary.

YEARLY OR 2000 HOURS:

Replace belt.

Replace hydraulic oil and filter with Graco hydraulic oil

169236 (5 gallon/20 liter) or 207428 (1 gallon/3.8 liter)

and filter 116909.

SPARK PLUG:

Use only BPRGES or W20EPR-U

(NIPPONDENSO) plugs. Gap plug to 0.028 - 0.031 in

(0.7 - 0.8 mm). Use spark plug wrench when installing or

removing plug.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the Pressure

Relief Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

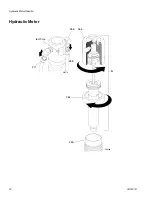

ti9686a

O

I

I

O

OFF

ON

Electric Models

Single Phase

Electric Models

Three Phase

Gas Models

ti7529a

ti18812a

TIA

ti5266

b