Operation

311075ZAB

25

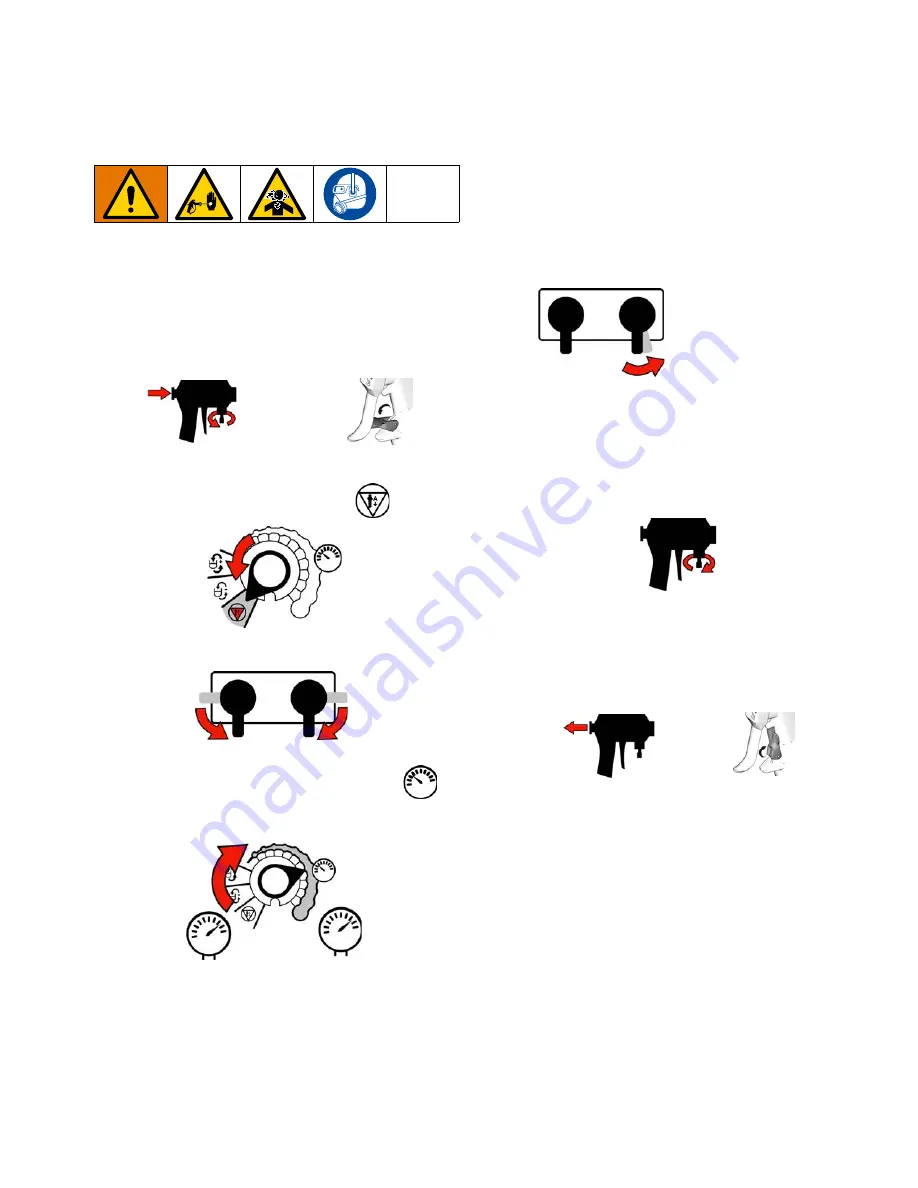

Spraying/Dispensing

NOTE:

For air operated guns only: Air is supplied to the

spray gun with the gun piston safety lock or trigger

safety lock engaged and gun fluid manifold valves A and

B closed (if present).

If using 2K Manual Dispense Valve, see dispense valve

instruction manual.

1. Set the function knob to Stop Park

.

2. Set the Spray valves to Spray.

3. Turn the function knob to Pressure Adjust

.

Keep turning to the right until the fluid pressure

gauges show desired pressure.

NOTE:

Use lower pressures for joint filling applications.

4. Check the fluid pressure gauges to ensure proper

pressure balance. If imbalanced, reduce the

pressure of the higher component by

slightly

turning the Spray valve for that component toward

Recirc, until the gauges show balanced pressures.

The pressure imbalance alarm (Status Code 1) is

inactive for 10 sec after entering spray pressure

mode, to allow time to balance pressures.

NOTE:

Watch the gauges for 10 seconds to be sure the

pressure holds on both sides and the pumps are not

moving.

5. Open gun fluid manifold valves A and B

(impingement mix guns only).

NOTE:

On impingement guns, never open the fluid

manifold valves or trigger the gun if pressures are

imbalanced.

6. Disengage the piston safety lock or the trigger

safety lock.

7. Test spray onto cardboard or plastic sheet. Verify

that material fully cures in the required length of

time, and is the correct color. Adjust the pressure

and temperature to get desired results. The

equipment is ready to spray.

Fusion

MD2

In this example, B side

pressure is higher, so

use the B side valve to

balance pressures.