14

308069

Maintenance

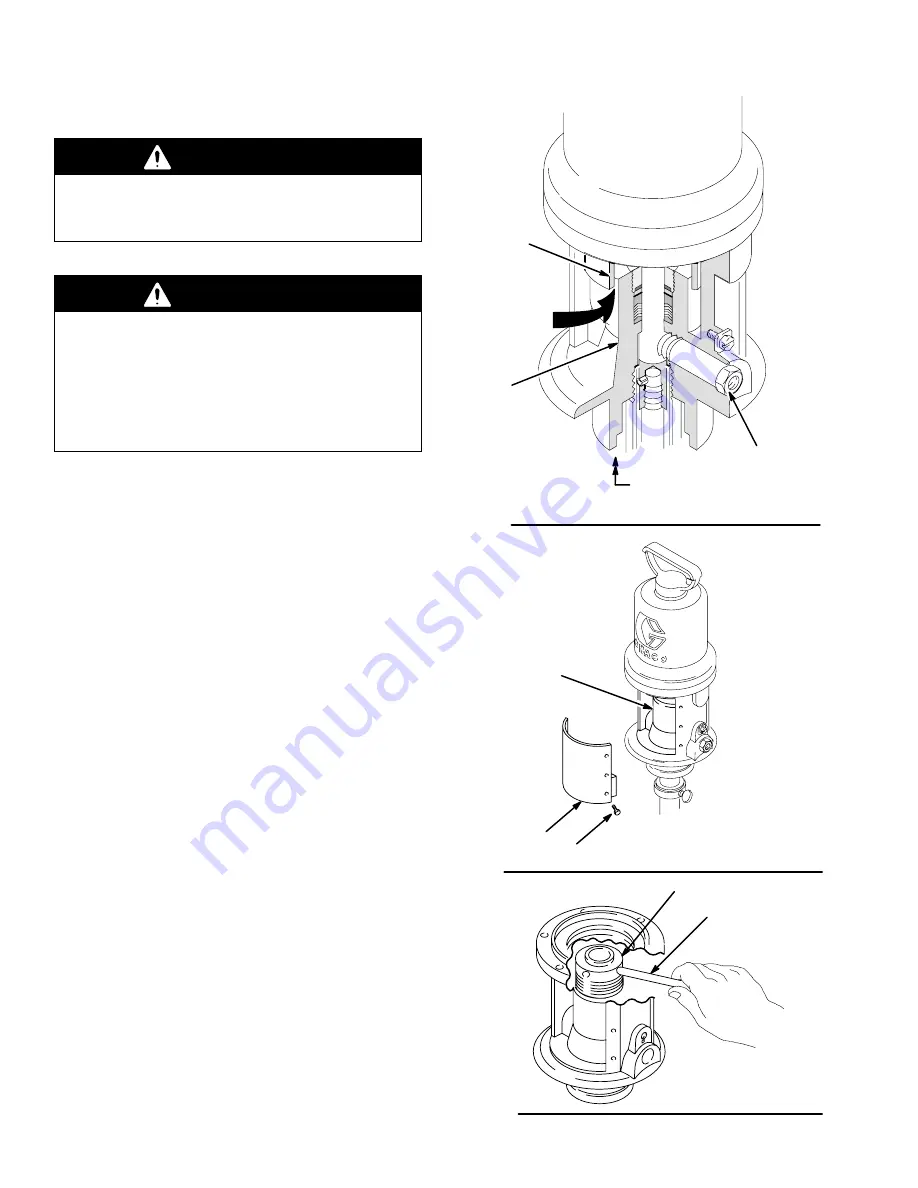

Pump packing nut adjustment

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 8.

WARNING

Keep your hand and fingers away from the piston

when it is moving. As the piston moves into the

pump base it can amputate fingers or break tools

caught between the moving parts. Note the pinch

point shown in Fig. 12. Be sure all air and fluid

pressure is fully relieved before adjusting the piston

or packing nut to reduce the risk of amputation.

NOTE: Perform this adjustment if: (a) material drips

steadily from the air motor weep hole, which indicates

the packings are too loose, or (b) the pump requires

more than 35 psi (244 kPa, 2.4 bar) air pressure to

cycle when the gun is triggered, which indicates the

packings are too tight.

1.

Relieve the pressure.

2.

Remove the six screws (24) using a 1/4” nut driver.

Remove the muffler plate (20).

See Fig. 13.

3.

Check to see that the air motor piston is at the top

of the stroke. If it is not, first read the warning

above. Then, while keeping your fingers away

from moving parts, apply very low pressure air to

the air inlet to move the piston up. Close the air

regulator and disconnect the air supply hose.

Refer to Fig. 12.

4.

Use a 1/4” diameter rod to tighten the packing nut.

First loosen the nut, then tighten snugly, and finally

tighten 1/4 turn more. See Fig. 14.

5.

Replace the muffler cover, and the six screws.

See Fig. 13.

6.

Reconnect the air line. After the pump is started, it

should run at 20 psi (1.5 bar) with no load. Startup

may require additional air pressure.

WEEP HOLE LOCATED

OPPOSITE FLUID OUTLET

AND IN BOTTOM OF BASE

Fig. 12

BASE

PISTON

PINCH POINT

FLUID

OUTLET

Fig. 13

24

20

BASE

Fig. 14

1/4” DIA. ROD

PACKING NUT