Rev. A 92149901

8

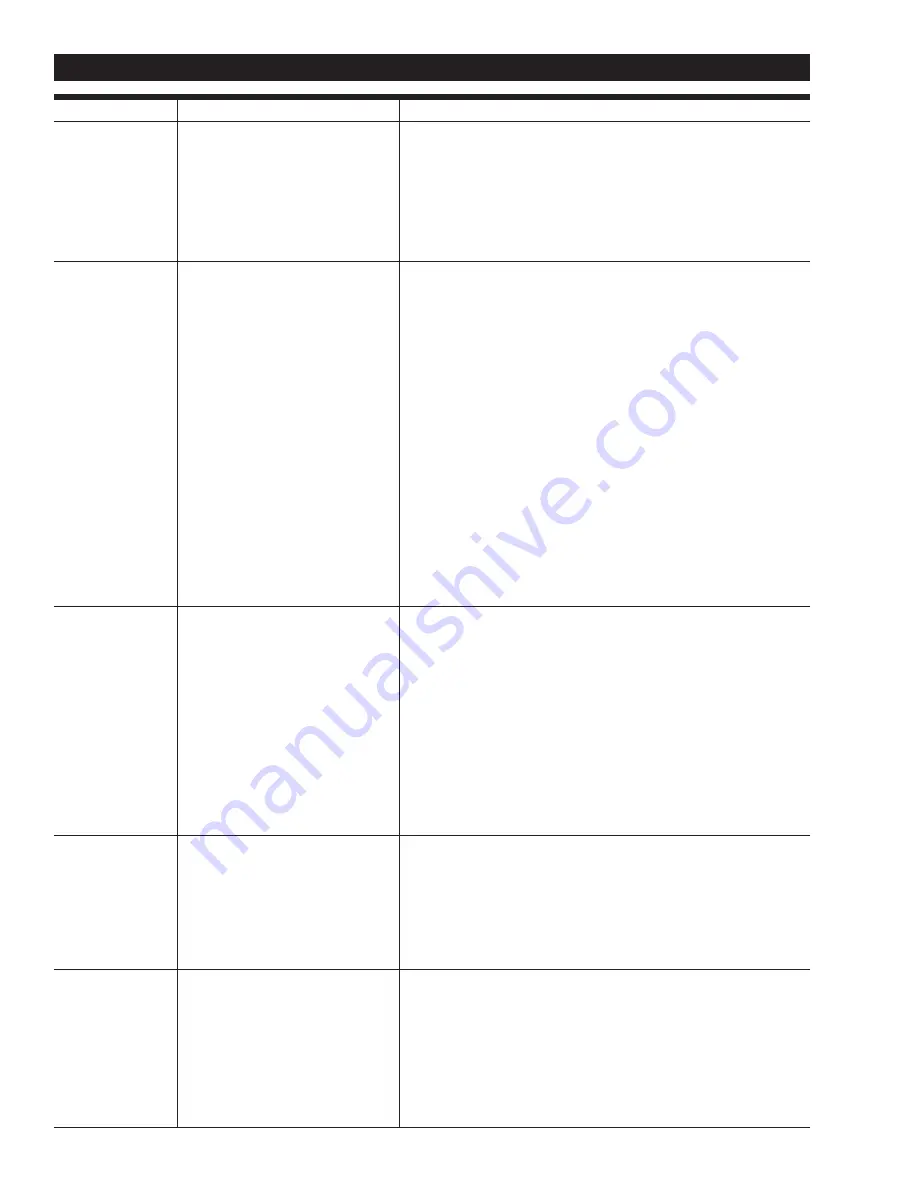

TROUBLESHOOTING

SYMPTOM

PROBABLE CAUSE

CORRECTIVE ACTION

A. MOTOR DOES

NOT RUN

1. Auxiliary temperature-limiting device

tripped

Turn pump switch off. Allow motor to cool approximately 30 minutes. Device

resets automatically. Try again.

2. Switch’s circuit breaker tripped

Turn power off at source. Determine source of high amp draw. Correct problem.

Make sure pump switch is in off position before restoring power. Restore power

to pump. Circuit breaker is reset manually by turning pump’s power switch off

and on

3. Switch defective

Remove switch coverplate and inspect switch. Replace, if necessary.

4. Motor burned out

Replace motor as described in the Repair Section.

B. MOTOR RUNS

BUT DOES NOT

PUMP FLUID

1. Drive key broken

Remove gear coverplate and replace drive key. Make sure gears turn freely

with the key removed.

2. Suction pipe clogged, damaged, or

missing

Remove pump from tank. Inspect suction pipe. Clean or replace, as necessary.

3. Gear coverplate or O-ring damaged

Remove and inspect the coverplate and O-ring. Replace, as necessary. Refer

to the Repair Section on Servicing O-rings.

4. Strainer clogged or defective

Remove strainer coverplate. Remove and clean strainer. Install again.

5. Bypass poppet O-ring worn or missing Inspect the O-ring, using instructions in the Repair Section. Replace, if

necessary.

6. Bypass poppet O-ring dirty

Remove poppet assembly and clean poppet and cavity.

7. System air leak

Tighten all pump fittings and connections. Inspect suction pipe for leaks or

damage.

8. System air lock

This can occur if external filter, meters, or an off-the-shelf automatic nozzle

is being used. To correct, remove the pipe plug in the top outlet port and

fill the gear cavity with fuel. Use of a factory-supplied automatic nozzle is

recommended.

9. Poor connections or low voltage

Make sure electrical connections are secure. Check power source.

10. Fuel level low

Fill tank.

11. Bypass poppet binding or damaged

Remove the bypass poppet, spring, and O-ring. Clean cavity. Inspect and

replace components, as necessary.

C. LOW

FLOWRATE

1. Poor connections or low voltage

Make sure electrical connections are secure. Also check power source.

2. Strainer partially clogged

Remove the strainer coverplate. Remove and clean the strainer. Install again.

3. Suction pipe clogged or damaged

Remove pump from tank. Inspect suction pipe. Clean or replace, as necessary.

4. Fuel tank empty

Fill tank.

5. Using off-the-shelf automatic nozzle

Factory-supplied automatic nozzle is recommended.

6. System air leak

Tighten all pump fittings and connections. Inspect suction pipe for leaks or

damage. Replace, as necessary.

7. Suction pipe too close to tank bottom Suction pipe must have at least 1/4 in. (0.6 cm) clearance from bottom of the

tank.

8. Bypass poppet spring weak

Remove the bypass poppet and inspect spring. Replace, if necessary.

9. Discharge hose too long

Long hoses reduce flow rate. Shorten hose.

D. MOTOR

STALLS WHEN

OPERATING IN

BYPASS MODE

1. Running too long in bypass mode

Limit bypass operation to 10 minutes.

2. Gears worn

Remove gear coverplate and inspect gears and drive key. Make sure gears

turn freely with the key removed. Replace, if worn.

3. Wiring defective

Use Wiring instructions in the Installation Section to ensure proper connections.

4. Bypass poppet binding or damaged

Remove the bypass poppet, spring, and O-ring. Clean cavity. Inspect

components and replace, as necessary.

5. Motor defective

Replace motor as described in the Repair Section

E. RAPID

OVERHEAT OF

MOTOR

1. Duty cycle too long

Pump operation should not exceed the standard duty cycle of 30 minutes ON,

and 30 minutes OFF. Allow the pump to cool for 30 minutes.

2. Strainer clogged

Remove strainer coverplate. Remove and clean strainer. Install again.

3. Suction pipe clogged or damaged

Remove pump from tank. Inspect suction pipe. Clean or replace, as necessary.

4. Gears worn

Remove gear coverplate and inspect gears and drive key. Make sure gears

turn freely with key removed. Replace, if necessary.

5. Fuel level low

Fill tank.

6. Running too long in bypass mode

Limit bypass operation to 10 minutes

Содержание M-1115S

Страница 11: ......