28

*NOTE: Please contact your distributor or our website for the applicable product data book referred to in this manual.

Gas Line

Gas

Shutoff

Valve

Gas Line

To Furnace

Drip Leg Cap

With Fitting

Manometer Hose

Manometer

Open To

Atmosphere

Measuring Inlet Gas Pressure (Alt. Method)

NOTE:

At either location, a hose fitting must be installed prior to

making the hose connection.

3.

Turn ON the gas supply and operate the furnace and all

other gas consuming appliances on the same gas supply

line.

4.

Measure furnace gas supply pressure with burners firing.

Supply pressure must be within the range specified in the

Inlet Gas Supply Pressure

table.

Propane Gas

Natural Gas

Inlet Gas Supply Pressure

Minimum:5.0" W.C. Maximum :10.0" W.C.

Minimum:11.0" W.C. Maximum :13.0" W.C.

If supply pressure differs from above, make necessary adjustments

to pressure regulator, gas piping size, etc., and/or consult with

local gas utility.

5.

Turn OFF gas to furnace at the manual shutoff valve and

disconnect manometer. Reinstall plug before turning on

gas to furnace.

6.

Turn OFF any unnecessary gas appliances started in step

3.

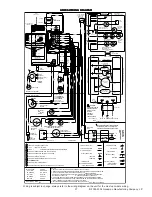

W

HITE

-R

ODGERS

36G22 G

AS

V

ALVE

The line pressure supplied to the gas valve must be within the

range specified in the

Inlet Gas Supply Pressure

table. The supply

pressure can be measured at the gas valve inlet pressure tap or at

a hose fitting installed in the gas piping drip leg. The supply pres-

sure must be measured with the unit OFF. To measure inlet pres-

sure, use the following procedure.

Pressure Regulator

Adjustment

(Under Cap Screw)

Gas Valve

On/Off

Selector

Switch

INLET

OUTLET

Inlet Pressure

Tap

Outlet Pressure

Tap

White-Rodgers Model 36G22

1.

Turn OFF gas to furnace at the manual gas shutoff valve

external to the furnace.

2.

Using 3/32 hex wrench, loosen inlet pressure tap screw

one turn.

3.

Connect a 5/16 inch hose and calibrated water manometer

to the gas valve inlet pressure tap. The hose should overlap

the tap by 3/8 inch.

4.

Turn ON the gas supply and operate the furnace

5.

Leak test. Using a leak detection solution or non-chlorine

soap suds, check for leaks at hose connection. Bubbles

forming indicate a leak. SHUT OFF GAS AND FIX ALL LEAKS

IMMEDIATELY BEFORE PROCEEDING TO NEXT STEP!

6.

Measure furnace gas supply pressure. Supply pressure

must be within the range specified in the

Inlet Gas Supply

Pressure

table.

If supply pressure reading differs from the table, make

necessary adjustments to pressure regulator, gas piping

size, etc., and/or consult with local gas utility.

7.

Turn OFF gas to furnace at the manual shutoff valve and

disconnect manometer and hose. Reinstall plug before

turning on gas to furnace.

8.

Seal pressure port. Tighten inlet pressure tap screw

clockwise 7 in-lbs. minimum.

9.

Retest for leaks. If bubbles form, shut down gas and fix

leaks immediately.

10. Turn valve switch ON.

G

AS

M

ANIFOLD

P

RESSURE

M

EASUREMENT

AND

A

DJUSTMENT

CAUTION

T

O PREVENT UNRELIABLE OPERATION OR EQUIPMENT DAMAGE, THE GAS

MANIFOLD PRESSURE MUST BE AS SPECIFIED ON THE UNIT RATING PLATE.

O

NLY MINOR ADJUSTMENTS SHOULD BE MADE BY ADJUSTING THE GAS VALVE

PRESSURE REGULATOR.

W

HITE

-R

ODGERS

36F22 G

AS

V

ALVE

Only small variations in gas pressure should be made by adjust-

ing the gas valve pressure regulator. The manifold pressure must

be measured with the burners operating. To measure and adjust

the manifold pressure, use the following procedure.

1.

Turn OFF gas to furnace at the manual gas shutoff valve

external to the furnace.

2.

Connect a calibrated water manometer (or appropriate gas

pressure gauge) at the gas valve outlet pressure tap (refer

to gas valve figure in previous section).

3.

Turn ON the gas supply and operate the furnace.

4.

Measure gas manifold pressure with burners firing. Adjust

manifold pressure using the

Manifold Gas Pressure

table

shown.

Manifold Gas Pressure

Natural Gas

3.5" w.c.

Propane Gas

10.0" w.c.

The final manifold pressure must not vary more than ± 0.3 “ w.c.

from the above specified pressures. Any necessary major changes

in gas flow rate should be made by changing the size of the burner

orifice.

5.

To adjust the gas valve pressure regulator, remove the

regulator cap.

6.

Turn the adjustment screw clockwise to increase the

pressure, or counterclockwise to decrease the pressure.

7.

Securely replace the regulator cap.

8.

Turn OFF gas to furnace at the manual shutoff valve and

Содержание GMS95

Страница 34: ...34...