18

meter for one complete revolution. If this is a 2 cubic

foot dial, divide the seconds by 2; if it is a 1 cubic foot

dial, use the seconds as is. This gives the seconds

per cubic foot of gas being delivered to the unit.

3.

INPUT=GAS HTG VALUE x 3600 / SEC. PER

CUBIC FOOT

Example:

Natural gas with a heating value of 1000

BTU per cubic foot and 34 seconds per cubic foot as

determined by Step 2, then:

Input = 1000 x 3600 / 34 = 106,000 BTU per Hour.

NOTE:

BTU content of the gas should be obtained

from the gas supplier. This measured input must not

be greater than shown on the unit rating plate.

4.

Relight all other appliances turned off in step 1. Be

sure all pilot burners are operating.

Main Burner Flame Check

Flames should be stable, soft and blue (dust may cause

orange tips but they must not be yellow) and extending

directly outward from the burner without curling, floating or

lifting off.

Heat Pump Start-Up Procedure Cooling

Note:

The reversing valve is energized when the

thermostat is placed in the cooling position. A clicking

sound should be noticeable from the reversing valve. By

lowering the temperature setting to call for cooling, the

contractor is energized. The compressor, blower and fan

should then be running.

1.

Turn thermostat system switch to “Cool,” and fan-

switch to “Auto” and turn temperature setting as high

as it will go.

2.

Inspect all registers and set them to the normal open

position.

3.

Turn on the electrical supply at the disconnect.

4.

Turn the fan switch to the “ON” position. The blower

should operate after a 10 second delay.

5.

Turn the fan switch to “Auto” position. The blower

should stop after a 60 second delay.

6.

Slowly lower the cooling temperature until the unit

starts. The compressor, blower and fan should now be

operating. Allow the unit to run 10 minutes, make sure

cool air is being supplied by the unit.

7. Turn the temperature setting to the highest position,

stopping the unit. The indoor blower will continue to

run for 60 seconds.

8. Turn the thermostat system switch to “OFF” and

disconnect all power when servicing the unit.

Heating

1.

Turn the thermostat system switch to “HEAT” and fan

switch to “AUTO”.

2.

Slowly raise the heating temperature setting. When

the heating first stage makes contact, stop raising

the temperature setting. The compressor, blower and

fan should now be running with the reversing valve in

the de-energized (heating) position. After giving the

unit time to settle out, make sure the unit is supplying

heated air.

valve external to the furnace.

2.

Turn off all electrical power to the system.

3.

Back outlet pressure test screw (inlet/outlet pressure

boss) out one turn (counterclockwise, not more than

one turn).

4.

Attach a hose and manometer to the outlet pressure

boss of the valve.

5.

Turn ON the gas supply.

6.

Turn on power and energize main (M) solenoid. Do

not energize the HI solenoid.

7. Measure gas manifold pressure with burners firing.

Adjust manifold pressure using the Manifold Gas

Pressure table.

8. Remove regulator cover screw from the low (LO)

outlet pressure regulator adjust tower and turn screw

clockwise to increase pressure, or counterclockwise

to decrease pressure.

9.

Energize main (M) solenoid as well as the HI

terminal.

10.

Remove regulator cover screw from the HI outlet

pressure regulator adjust tower and turn screw

clockwise to increase pressure, or counterclockwise

to decrease pressure.

11.

Turn off all electrical power and gas supply to the

system.

12.

Remove manometer hose from outlet pressure boss.

13.

Turn outlet pressure test screw in to seal pressure

port (clockwise, 7 in-lb minimum).

14.

Turn on electrical power and gas supply to the

system.

15.

Turn on system power and energize valve.

16.

Using a leak detection solution or soap suds, check

for leaks at pressure boss screw. Bubbles forming

indicate a leak. SHUT OFF GAS AND FIX ALL

LEAKS IMMEDIATELY.

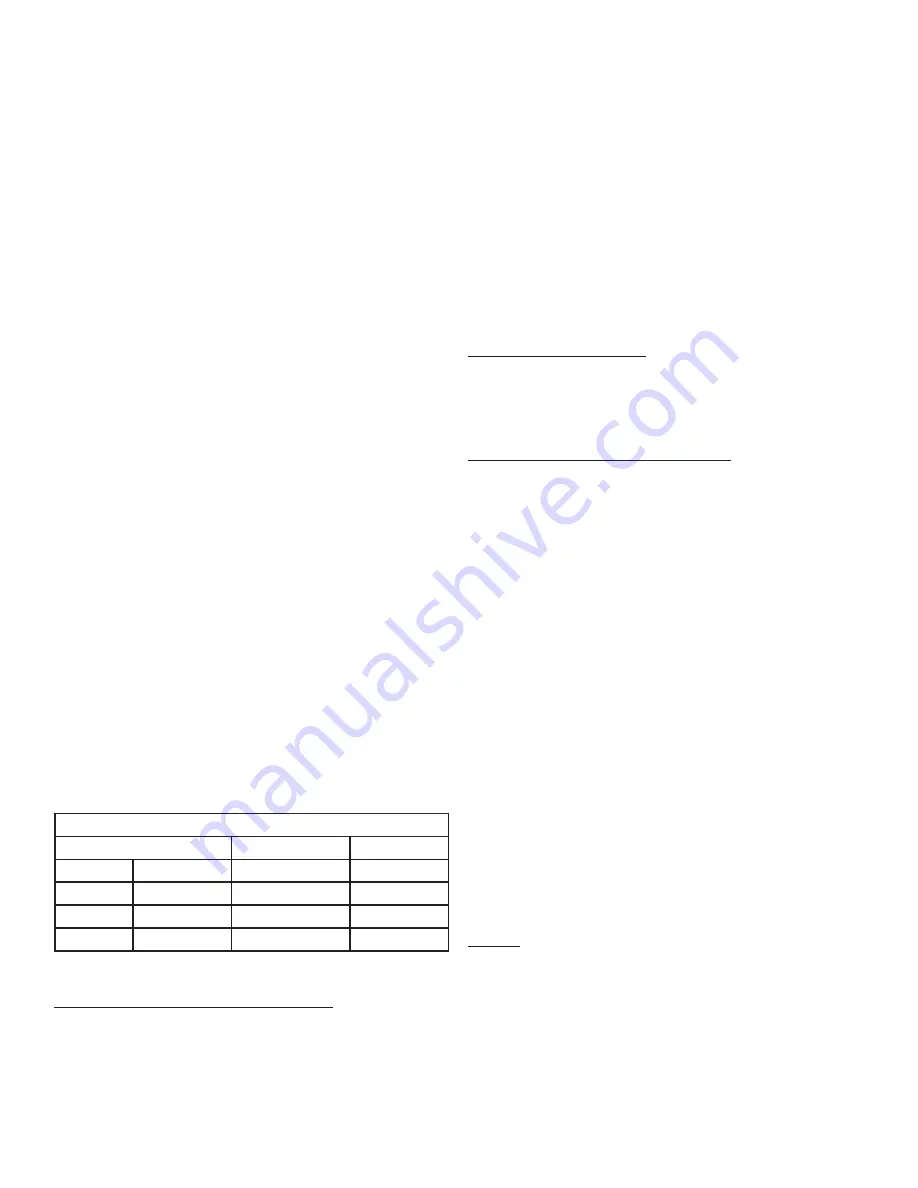

Manifold Gas Pressure

Gas

Range

Nominal

Natural

Low Stage

1.6 -2.2” W.C.

2.0” W.C.

High Stage 3.2 - 3.8” W.C.

3.5” W.C.

Propane

Low Stage

5.7 - 6.3” W.C.

6.0” W.C.

High Stage 9.7 - 10.3” W.C. 10.0” W.C.

Manifold Gas Pressure

Gas BTU Input (Natural Gas Only) Check

To measure the gas input use a gas meter and proceed as

follows:

1.

Turn off gas supply to all other appliances except the

unit.

2.

With the unit operating, time the smallest dial on the

Содержание 209319576

Страница 34: ...34 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Страница 35: ...35 THIS PAGE IS INTENTIONALLY LEFT BLANK...