16

thermostat call for FAN is removed.

Air flow Measurement and Adjustment

Please review the Duct Work section before proceeding

with the airflow measurements and adjustments in this

section.

Unit blower curves (see Specification Sheets) are based

on external static pressure (ESP per in/W.C.). The

duct openings on the unit are considered internal static

pressure. As long as ESP is maintained, the unit will deliver

the proper air up to the maximum static pressure listed for

the CFM required by the application (i.e. home, building,

etc.)

In general, 400 CFM per ton of cooling capacity is a rule

of thumb. Some applications depending on the sensible

and latent capacity requirements may need only 350 CFM

or up to 425 CFM per ton. Check condition space load

requirements (from load calculations) and equipment

expanded ratings data to match CFM and capacity.

After unit is set and duct work completed, verify the ESP

with a 1-inch inclined manometer with pilot tubes or a

Magnahelic gauge and confirm CFM to blower curves in the

Specification Sheets.

NOTE:

Never run CFM below 350 CFM per ton, evaporator

freezing or poor unit performance is possible.

Air Flow Adjustments For Indoor Blower Motor

EEM Motor

Adjust the CFM by changing the 24V low voltage lead at

the speed terminal block on the motor. (T1, T2, T3, T4,

T5). See Blower Performance Data in the appendix for

airflow delivered at each speed tap.

NOTE:

Factory set T1 (G, fan and low stage gas heat), T2

(high stage gas heat, T4 (nominal heat pump / cooling).

T3 is for optional low speed cooling and heat pump. T5 is

for optional high speed cooling and heat pump.

START-UP, ADJUSTMENTS, AND CHECKS

Heating Start-up ( Natural Gas / LP)

This unit is equipped with an electronic ignition device to

automatically light the main burners. It also has a power

vent blower to exhaust combustion products.

On new installations, or if a major component has been

replaced, the operation of the unit must be checked.

Check unit operation as outlined in the following

instructions. If any sparking, odors, or unusual sounds are

encountered, shut off electrical power and check for wiring

errors, or obstructions in or near the blower motors.

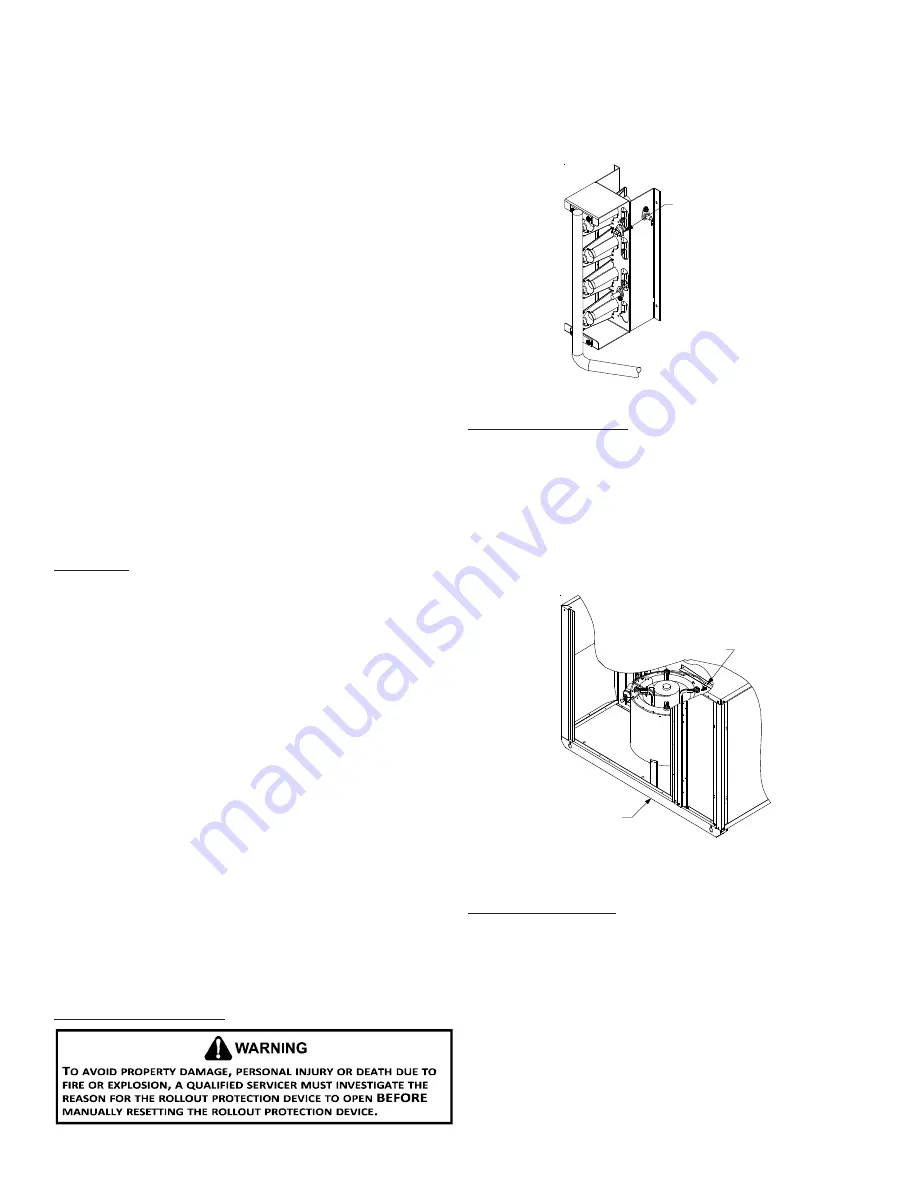

Rollout Protection Control

The rollout protection device opens, cutting power to the

gas valve, if the flames from the burners are not properly

drawn into the heat exchanger. The rollout protection

device is located on the burner bracket. The reason for

elevated temperatures at the control must be determined

and repaired prior to resetting this manual reset control.

Rollout Protection

Rollout Protection on Burner Bracket

Secondary Limit Control

The secondary limit control is located on the top of the

blower scroll assembly. This control opens when elevated

temperatures are sensed. Elevated temperatures at the

control are normally caused by blower failure.

If the power to the unit is interrupted during the heating

cycle, it may cause the secondary limit to trip. Once the

blower compartment temperature drops below the limit

reset temperature, the limit will automatically reset.

Secondary

Control Limit

Back of Unit

Secondary Control Limit

Pre-Operation Checks

1.

Close the manual gas valve external to the unit.

2.

Turn off the electrical power supply to the unit.

3.

Set the room thermostat to its lowest possible setting.

4.

Remove the heat exchanger door on the side of the

unit by removing screws.

5.

This unit is equipped with an ignition device which

automatically lights the main burner. DO NOT try to

light burner by any other method.

6.

Move the gas control valve switch to the OFF

position. Do not force.

Содержание 209319576

Страница 34: ...34 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Страница 35: ...35 THIS PAGE IS INTENTIONALLY LEFT BLANK...