20

Pump

Diaphragm pumps are a positive displacement

pump that utilise a number of rubber

diaphragms and non-return check valves to

pump (displace) the fluid. Diaphragm pumps

are very well suited to chemical spraying

applications. To ensure that you get the most

from your pump, follow the information here to

use it correctly. Proper operation and periodic

maintenance are essential in obtaining the

best possible performance from your sprayer

over time.

IMPORTANT:

Never overfill pump with oil as

damage to seals & oil bowl may result. Do not

operate diaphragm pumps above 600 RPM.

IMPORTANT:

The pump will perform optimally

close to, but not over 600 RPM. At speeds

much below 600 RPM, excessive pulsation will

occur. Speeds above 600 RPM are likely to

result in pump and diaphragm damage.

IMPORTANT:

Do not leave water in pump if

sprayer is to be left in a cold environment.

Frozen water inside the pump can cause

the housing to crack. Always allow any

frozen water inside the pump to thaw before

attempting to operate the pump.

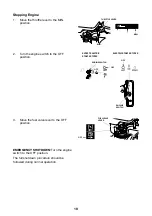

PREOPERATIONAL PROCEDURE

1. If sprayer is in a cold environment, make

sure that any frozen water present in

the pump is thawed before attempting

operation to avoid serious damage.

Ensure that the pump can be turned over

by hand before starting.

2.

Inspect all hoses to make sure they are

the correct size, fitted securely and that

there is no restriction or leaking.

3. Make sure that guards and covers are

fitted correctly to prevent accidental

injury.

4.

Make sure the strainer in the suction filter

is clean and correctly installed.

5.

Change the pump oil after the first 50

hours of operation and then after every

300-350 hours. Use only SAE 15W40

motor oil and do not overfill. Rotate pump

manually (by hand) to remove air locks

when filling with oil.

WHEN THE PUMP IS OPERATING

•

The oil should be visible in the bowl.

•

Frequently check the oil level and colour.

NOTE:

A change in either colour or level

indicates probable damage to diaphragm or

valves.

Stop the pump immediately.

POST OPERATIONAL PROCEDURE

1. Always flush pump with clean water at

the end of each spraying day. Prolonged

chemical contact can severely damage

seals and diaphragms.

2. Do not leave water in pump if sprayer is

to be left in a cold environment. Frozen

water inside the pump can cause the

housing to crack. Empty pump of all

water and run it dry for 15-20 seconds

then cover pump with a bag or similar

to keep it protected. If this has not been

done and there is a possibility there may

be frozen water in the pump and/or in the

lines, wait until any ice has completely

thawed before using pump again.