6

Burn Hazard

• Avoid contact around engine, pump

and gearbox area when at operating

temperature.

Entanglement Hazard

Rotating drives can cause serious injury or

even death when entanglement occurs. Keep

hands, feet, hair and clothing away from all

moving parts to prevent injury. Never operate

this machine with covers, shrouds, or guards

removed.

Stored Energy Hazard

Even when the machine is not operating,

energy can be stored in components such

as tyres, hoses and springs. Before working

on the machine, ensure that these parts are

relieved of their energy in a safe manner.

Overhead Hazard

Keep clear of overhead obstructions –

especially power lines as contact can be

fatal.

Do NOT stand or climb on machine when

near power lines.

Airborne Particles

• Always stand well clear of equipment

during operation.

• Any spray drift is dangerous and may be

hazardous to humans and other animals.

• When heating and welding components,

ensure that all paint and other such

materials are removed. Often hazardous

airborne particles and fumes are

generated from welding and heating.

Fluids Under Pressure

Fluids escaping from high pressure lines can

cause serious injury to skin. Hydraulic oil can

easily penetrate human skin. This hazard can

be avoided by relieving the pressure in the

system.

Do not disconnect any hoses, nozzles

or filters while equipment is operating.

Disconnecting these components while

under pressure may result in uncontrolled

fluid discharge which may be hazardous.

Be mindful of the location of pressurised

lines in the vicinity of the work area when

using equipment such as grinders, oxy

torches and welders. The two main risks are

that this equipment may easily cut through

the lines or the local heat generated near the

lines may cause them to rupture.

Ensure that all fittings and lines are fully/

tightly secured before re-pressurizing after

repairs.

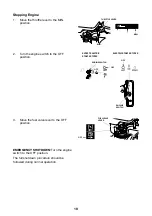

Lifting Machine

Before raising the machine off the ground:

• Ensure that the boom is in its closed

position.

•

Park up on a flat, level and firm area.

• Empty the spray tank where possible.

• Chock all wheels that remain on the

ground.

• Securely lift the machine using a jack and

support the machine on work stands.

• Do not work under the machine when

supported solely by a jack.

• Do not support the sprayer using

materials that may crumble.

Changing Wheels & Tyres

An experienced person with the correct

equipment should mount the wheels on the

sprayer.

When changing a wheel on the sprayer

ensure that the sprayer is on firm level

ground and the wheels are chocked.

Tyre Maintenance

Maintain correct tyre pressure at all times.

Inflation of tyres above or below the

recommended pressure exerts additional

pressure on the tyre, which may result in tyre

damage.

Extreme caution is required during the

inflation of tyres. If the tyre is inflated at a

rapid rate separation and/or explosion of the

rim can occur. This event can inflict serious

or fatal injuries to the operator.

•

Always use a tyre inflation gauge.

• Be proactive and continually check the

condition of your tyres.

• Do not weld, heat or modify the rim.

Machine Operation

• High speed turning places severe stresses

on the wheels and axles and should be

avoided. It is essential to observe the

effects of turning on the open spray

boom. Excessive turning speeds transmit

great stresses to the spray boom and

WILL CAUSE boom damage.

• When fully loaded, spray operations

should be carried out at a recommended

speed no greater 20 km/h. This speed