21

Pump Maintenance

The pump diaphragms are wearing

components that need to be replaced during

the life of the pump. Life expectancy depends

upon pump operation and maintenance and

task suitability.

MAINTENANCE GUIDELINES

• Pump diaphragms should be replaced

prior to diaphragm failure.

• Where the sprayer is used extensively,

the pump should be reconditioned once a

season, including replacing diaphragms,

seals and valve springs.

• It is recommended to keep a spare pump

repair kit (including diaphragms, seals,

valve o-rings and springs) on hand in case

of a breakdown.

• A change of oil colour indicates a pump

problem. The oil should be regularly

monitored when spraying so that any

problem is detected as soon as possible.

If the oil goes milky in colour, it is likely the

diaphragm has split and the spray mixture

has come into contact with the oil. If the

oil goes black (or dark grey), it is likely the

pump has overheated.

MAIN CAUSES OF PREMATURE

DIAPHRAGM FAILURE

• Blocked or incorrectly fitted suction filter

restricting flow to the pump.

• Incorrect air damper chamber pressure.

• Running pump at speeds greater than 600

RPM.

• Exceeding the 290 PSI pressure limit of

the pump.

• Failure to wash chemicals from pump after

use.

• Incompatibility of the diaphragm material

and the chemicals used.

DIAPHRAGM REPLACEMENT

When diaphragms require replacement it is

normal practice to replace the air damper

diaphragm at the same time.

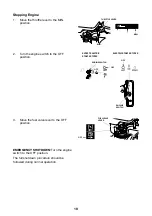

1. Flush pump with clean water to remove

chemical residue, then flush with

appropriate decontaminating agent (refer

to chemical label for decontamination

instructions).

2. Run pump dry for 15-20 seconds to

remove water.

3. Remove all air from air damper chamber

by pushing in air valve.

4. Remove pump from sprayer.

5. Remove pump manifolds and pump

heads.

NOTE:

Carefully note the position and

orientation of all heads, manifolds and

valves when disassembling pump. Failure to

reassemble correctly will result in severe pump

damage.

6. Drain oil from pump.

7. Remove diaphragms.

8. Remove cylinder sleeves.

9. Flush inside of pump with diesel.

10. Visually inspect inner workings of pump.

11. Reassemble with correct new diaphragms

only once satisfied with condition of pump.

12. Refill with SAE 15W40 oil. Rotate pump by

hand to remove air locks. Do not overfill.