6

Specifications

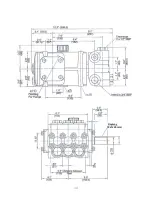

Model P435B

U.S. ................................. (Metric)

Volume .................................................... Up to 6.6 GPM ................ (25.0 LPM)

Discharge Pressure Continuous ............ Up to 3,625 PSI .............. (250 bar)

Inlet Pressure ......................................... -4.35 to 145 PSI .............. (-.3 to 10 bar)

Stroke ..................................................... 0.94” ................................ (24mm)

RPM ................................................................................................ Up to 1450 RPM

Plunger Diameter .................................... 0.708” .............................. (18mm)

Temperature of Pumped Fluids .............. Up to 160

o

F .................... (71

o

C)

Inlet Ports ........................................................................................ (2) 3/4" BSP

Discharge Ports .............................................................................. (2) 1/2" BSP

Shaft Rotation ......................................... Top of pulley towards manifold

Crankshaft Diameter .............................. 1.102” .............................. (28mm)

Key Width ............................................... .315” ................................ (8mm)

Shaft Mounting ................................................................................. Either side

1

Weight .................................................... 37 lbs. 6oz ...................... (17.0 kg)

CrankcaseCapacity ................................ 30 fl.oz. ........................... (0.89 liters)

Volumetric Efficiency @ 1450 ......................................................... (0.95)

Mechanical Efficiency @ 1450 ........................................................ (0.83)

Consult the factory for special requirements that must be met if the pump is

to operate beyond one or more of the limits specified above.

NOTES:

In order to drive the pump from the side opposite the present shaft

extension, simply remove the valve casing from the crankcase and

rotate the pumps 180 degrees to the desired position. Be certain to

rotate the seal case (item #20) as well, so that the weep holes are

down at the six o'clock position. Exchange the oil fill and the oil

drain plugs, also. Refer to the repair instructions as necessary for

the proper assembly sequence.

HORSEPOWER RATINGS:

The rating shown are the power

requirements for the pump. Gas

engine power outputs must be ap-

proximately twice the pump power

requirements shown above.

We recommend a 1.15 service factor

be specified when selecting an

electric motor as the power source.

To compute specific pump horse-

power requirements, use the following

formula:

HP = (GPM X PSI) / 1450

SPECIAL NOTE:

The theoretical gallons per revolution

(gal/rev) is 0.00455.To find specific

outputs at various RPM, use the formula:

GPM = 0.00455 x RPM

RPM

GPM

2000 PSI

2500 PSI

3000 PSI

3625 PSI

920

4.2

5.8

7.2

8.7

10.5

1050

4.8

6.6

8.3

9.9

12.0

1185

5.4

7.4

9.3

11.2

13.5

1315

6.0

8.3

10.3

12.4

15.0

1450

6.6

9.1

11.4

13.7

16.5

P435B HORSEPOWER

REQUIREMENTS

Содержание P435B

Страница 4: ...EXPLODED VIEW P455 4 ...

Страница 10: ...10 Keyway 8x7x45mm ...

Страница 11: ...NOTES 11 ...