9) Check surfaces of plunger

(16). Damaged surfaces

cause accelerated seal wear.

Deposits of all kinds must be

removed from the plungers.

IMPORTANT! Plunger

surfaces are not to be

damaged. If there are lime

deposits in the pump, care

must be taken that the drip-

return bore in parts (25) and

(26) ensure trouble-free

drip-return.

10) If the plunger pipe (16B) is

worn, remove tension screw

(16D) and remove along with

plunger pipe (16B). Check and

clean plunger surface (16A),

check oil scraper (16H). Cover

thread of tension screw (16D)

with a thin film of Loctite and

tighten carefully to 26 ft.-lbs.

(35NM).

IMPORTANT! Care must be

taken that glue does not get

between the plunger pipe

(16B) and centring sleeve

(16C). The plunger pipe

should not be strained by

eccentric tightening of the

tension screw or through

damage to front surface of

plunger, otherwise it is liable

to fracture.

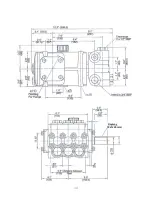

11) After installation of high

pressure seals (23 - Note:

P422 and P423, also have

a support ring), place seal

adaptor (20) with weep

seals & pressure ring

installed, weep return ring

(25) and high pressure

weep return ring (24) over

plungers. Slide valve casing

over plungers and seat

firmly. Replace the 8

socket head cap screws

(34) and tighten to 35 ft.-lbs.

in a crossing pattern

(as shown to the right).

8

7

6

5

4

2

1

3

TORQUE SPECIFICATIONS - P455

Position

Item#

Description

U.S

Metric

15

08390

Screw with Washer

216 in.-lbs.

24.4 N-M

16D

08399

Tension Screw

240 in.-lbs.

27.1 N-M

32

05544

Plug (P455)

125 ft.-lbs.

169.4 N-M

34

08484

Cap Screw

35 ft.-lbs.

47.5 N-M

REPAIR INSTRUCTIONS - P455

Contact Giant Industries for service school information. Phone: (419)

531-4600

8

Содержание P435B

Страница 4: ...EXPLODED VIEW P455 4 ...

Страница 10: ...10 Keyway 8x7x45mm ...

Страница 11: ...NOTES 11 ...