ITEM PART DESCRIPTION

QTY.

1

08377

Crankcase

1

2

08378

Oil Fill Plug with Gasket

1

3

06479

Crankcase cover

1

3A

07186

Oil Sight Glass w/ Gasket

1

4

08380

O-Ring

1

5

07109

Oil Drain Plug

1

5A

07182

Gasket for Oil Drain Plug

1

5B

08092

Plug with Gasket

1

6

01010

Screw

4

6A

01011-0400

Spring Washer

4

7

05290

Bearing Cover Open

1

8

05291

Bearing Cover Closed

1

8A

05292

Shim

3

8B

05293

Shim (May not be present)

1

9

01016

O-Ring

2

10

07114

Screw with Washer

8

11

07459

Radial Shaft Seal

1

12

05350

Taper Roller Bearing

2

13

08475

Crankshaft (P435)

1

13

08482

Crankshaft (P455)

1

14

08091

Fitting Key

1

15

08390

Connecting Rod Assembly

3

16

05484

Plunger Assy.,18mm

(Items 16A-16H)

3

16A

05352

Plunger Base

3

16B

08397

Plunger Pipe, 18mm

3

ITEM PART DESCRIPTION

QTY.

16D

08399

Tensioning Screwing

3

16E

07023

O-Ring

3

16F

07203

Backup Ring

3

16G

07258

Copper Washer

3

16H

06431

Oil Scraper

3

17

06790

Crosshead Pin

3

19

05444

Oil Seal

3

20

05534

Seal Case

3

21

07266

O-Ring

3

23

08477

V-Sleeve, 18mm

6

24

07929

Pressure Ring

3

25

08402

Weep Return Ring

3

26

05574

Manifold - Brass

1

27A

05543

Valve Assy.

6

27

05541

Valve Seat

6

28

05542

Valve Plate

6

29

07906

Valve Spring

6

30

07907

Valve Spring Retainer

6

31

07770

O-Ring

6

32

05544

Plug

6

33

05545

O-Ring

6

34

08484

Cap Screw

8

36

13434

Plug, 1/2" BSP

1

36A

06272

O-Ring (P455 Only)

1

37

07703

Plug, G 3/4"

1

P455B REPAIR KITS

Valve Assembly Kit - # 09644

Item

Part

#Description

Qty

27A

05543

Valve Assembly, Complete 6

33

05545

O-Ring

6

Oil Seal Kit - #09641

Item

Part #

Description

Qty

19

05444

Oil Seal

3

Plunger Packing Kit - # 09643

Item

Part

#Description

Qty

21

07266

O-Ring

3

23

08477

V-Sleeve

6

24

07929

Pressure Ring

3

P455 SPARE PARTS LIST

5

Содержание P435B

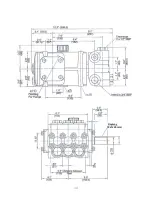

Страница 4: ...EXPLODED VIEW P455 4 ...

Страница 10: ...10 Keyway 8x7x45mm ...

Страница 11: ...NOTES 11 ...