10

ERR Mode

During operation of the press, if there

is a loss of signal from the temperature

sensor wire, the ERR display will

appear.

This is a safety feature that will shut off

the relay so the press will not overheat

aimlessly without a temperature signal.

Once the temperature signal is restored (no longer broken, or plugged

back into the control) the press will resume the temperature display, and

start heating if necessary. If ERR persists, contact support.

Over-Temp Alarm

If the press heats beyond the set

temperature by 40 degrees or greater,

the OverTemp alarm will sound.

This is a safety feature that warns the

operator of a possible thermal run-away

of the press. This means the press relay

may be locked in a heating position

where it will never stop heating, to a

possibly harmful temperature level.

If the OverTemp alarm sounds, set the temperature to a higher value

than the current actual temp. Wait 30 seconds and then reset the press to

your desired temperature and Watch Carefully. Do not let the press rise

to extremely high temps.

If it continues to rise, turn off the press and let it cool off to room

temperature. Turn the power back on and immediately set the temperature

to a low setting like 200°F. Wait for the press to heat up. When the press

displays “READY”, monitor the temperature and see if it continues to

heat to a level that the OverTemp alarm activates again. If so, contact

the factory.

Содержание Digital Knight DK16

Страница 1: ...1 Version 1 09 Digital Knight DK20 16x20 and DK16 14x16 Digital Clamshell...

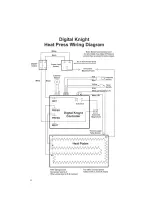

Страница 22: ...22 Wiring Diagram...