are corrosive or abrasive or detergents containing

chlorine or ammonia.

SERVICE

The Air Cleaner when operating normally will have

the fan running and the performance indicator light

ON

. If

this is not the case the see the Troubleshooting Guide for

probable causes and remedies.

Testing For High Voltage At Power Board

For the following test you will need to have the hinged

cover open with the

collecting cell out of the unit

.

1. Remove the hinged cover and the cover panel to the

power box. Push a screwdriver into the slot to defeat

the interlock switch and turn the Air Cleaner

ON

.

2. With a long shafted screwdriver, with a plastic handle,

short between the grounded side of the power box

and the HV1 terminal of the power board.

3. If you draw a good spark, there is high voltage from

the power board.

Measuring High Voltage At Power Board

A high voltage meter capable of measuring up to

10,000 VDC is required to test the voltage.

1. The Air Cleaner should be

ON

with the cell installed

and the cell access door closed. The Air Cleaner

should be on at least 5 minutes to allow voltage to

stabilize.

2. Remove the hinged cover and the cover panel from

power box.

3. Connect the ground of the high voltage meter to

ground stud in the power box.

4. Turn the Air Cleaner

ON

, and defeat the interlock

switch.

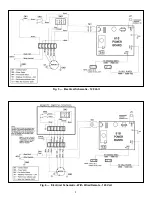

5. Check terminals HV1 and HV2 on the power board to

determine if voltage is present. See Fig. 5 for values..

5. If no voltage is present, remove the cell from the Air

Cleaner.

a. Check the voltage at HV1 and HV2 again.

b. If voltage is present, the problem is with the cell

or the wiring to the copper contacts.

c. Check the condition of the copper contacts and

wiring.

d. If the contacts are not bent and the wiring is OK,

the problem is with the cell. See the

Troubleshooting Guide for more information.

e. If there is no voltage with the cell removed, check

the power board, system switch and transformer

to make sure that they are functioning correctly.

6. If there is voltage present, but the performance light

does not come on, replace the light.

7. The high voltage can be adjusted with the

potentiometer on the power board if required.

Replacing A Performance Light

Before replacing the performance light, turn

OFF

power to the Air Cleaner at the source.

1. Remove the cover and the power box cover panel.

2. Disconnect the performance light wiring connected to

the neon lamp terminals (P5 and P6) on the power

board. Carefully cut the wire ties from the wire

bundle.

3. Push the light out through front of power box.

4. Push the new light into the power box.

5. Connect the wiring to the neon lamp terminals on the

power board, P5 and P6. Route the wires away from

the high voltage section of the power board.

6. Replace cover panel and close the cover.

7. Return power to Air Cleaner. Test light.

Replacing A Power Board

Before replacing the power board, turn

OFF

power to

the Air Cleaner at the source.

1. Remove the cover and the power box cover

panel.

2. Disconnect the wiring from the neon lamp, HV1, HV2

and 24 V terminals. Make note of position of wires.

3. Remove the hex nuts from the power board.

4. Remove the power board from the studs.

5. Place the new board onto studs with the 24 volt input

close to the transformer.

5

Fig. 4

—

DAX Detergent is

available in 35 ounce (1 litre)

spray bottles or 1 gallon (4.54 L)

and 4.8 gallons (22 L) containers

from your installer or dealer.

WARNING

Electronic Air Cleaners use high voltage (low

amperage). Only trained personnel should perform

service.

USE CAUTION!

Electric shock can cause

injury or death.

CAUTION

For most troubleshooting the cell should be

removed from the Air Cleaner.

A short in the cell will

cause the power board to shutdown and the

performance light will stay off. Unless otherwise

directed remove the cell from the unit when testing.

WARNING

When performing LIVE tests in the power box

NEVER

touch any parts other then what are mentioned in the

tests. Components carry dangerous voltages and

extreme care must be taken.