17

Connections to the unit can be made via a single screened multi-

core cable and one 9-way D-type male connector or via separate

signal and power connectors (supplied). The second option is

recommended for distances of >75m.

Currently there are three versions of display software, one for

MPS (PM-SC and PM-IC), one for engine controllers (PM-GC and

PM-PC) then finally one version for PM-GC and PM-PC Bifuel.

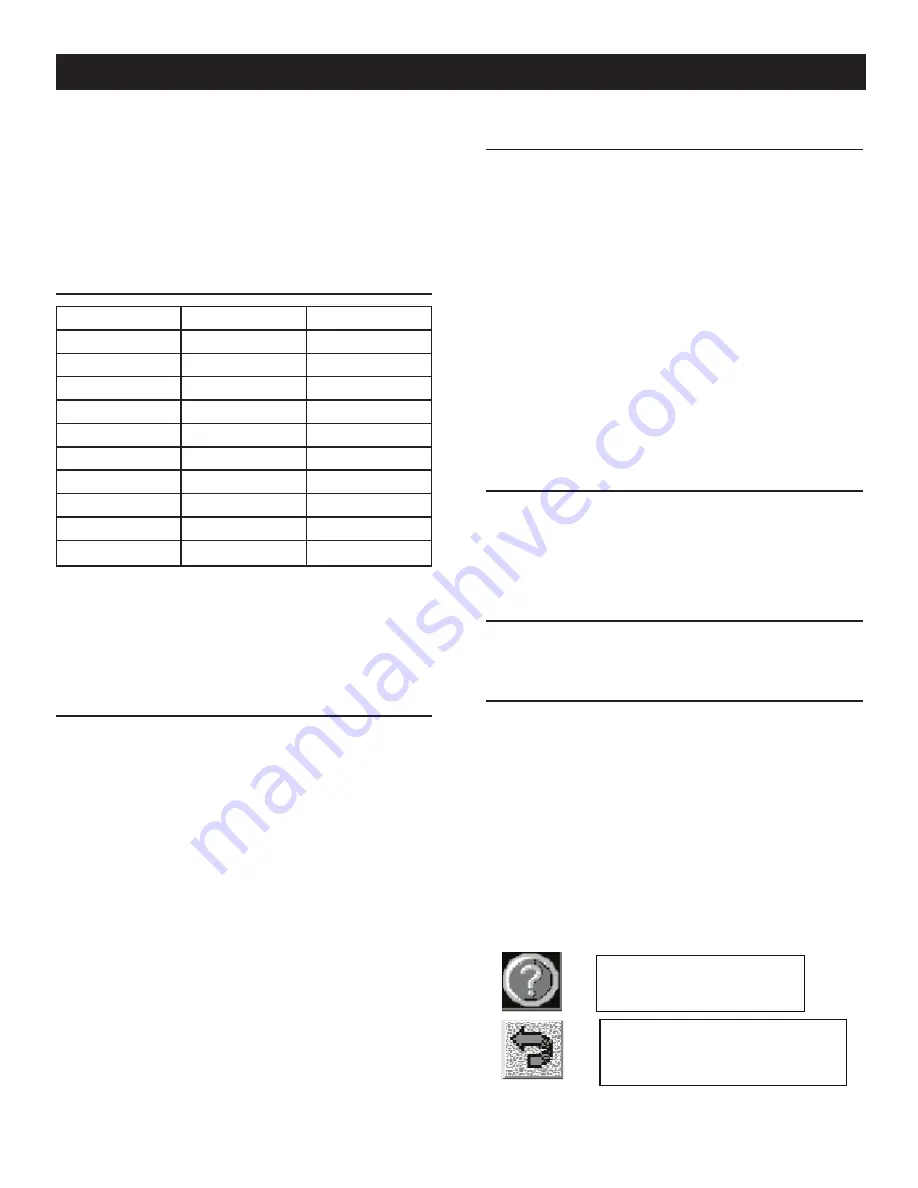

3.17.1 CONNECTION DETAILS

Display Pin

Connection

Controller Pin

1

-

2

GND (screen)

-

3

RS485-

J6 - 21

4

-

-

5

GND

J6 - 11

6

-

7

+24V Supply

J6-12

8

RS485+

J6 - 20

9

-

-

The power supply should be in the range 18-30Vdc @ 0.4A, this

is normally supplied from the controller. J6 pin 11 is Gnd and pin

12 is +24v. The case earth screw should be connected to an earth

point in the enclosure via a 2.5mm diameter wire.

The multicore cable should have 24AWG wires for distances up to

75m, above this 18AWG should be used.

3.17.2 CONTRAST ADJUSTMENT

Contrast may need to be adjusted depending on the incident light-

ing conditions.

EITHER

1. Switch on the power to the unit.

2. During the initialization phase, a menu will appear briefly.

Press the CONFIG button.

3. Now use the CO and – keys to adjust contrast.

OR

1. During normal operation, select the MAINTENANCE screen

and then use the co and – buttons to adjust the

contrast. For power manager versions select the ADJUST

DISPLAY screen.

3.17.3 CALIBRATION

As the unit can be mounted at different angles, there may be cali-

bration required to compensate for parallax errors.

EITHER

1. Switch on the power to the unit.

2. During the initialization phase, a menu will appear briefly.

Press the CONFIG button.

3. Now use the CALIBRATE button to calibrate the screen

4. Five calibration crosses appear in succession on the screen,

touch them as they appear.

5. Once this is done, you have 30 seconds to touch the screen

at any position to “accept” the calibration.

OR

1. During normal operation, select the MAINTENANCE screen

and then the “Calibrate Touchscreen” button. For power man-

ager versions select the ADJUST DISPLAY screen.

2. Follow steps 4 & 5 above.

3.17.4 CLEANING

Grease will occur on the screen as a result of normal operation.

This can be cleaned with a soft cloth. In order to prevent operating

the touchscreen during this time, select the MAINTENANCE page

and choose the “Clean Screen” option. For power manager ver-

sions select the ADJUST DISPLAY screen.

3.17.5 TOUCHSCREEN OPERATION

Operate the touch screen with a finger only, do not use pens or

other pointed objects.

3.17.6 FUNCTIONALITY

The display screen has been devised as a way to examine data

within the supplied product. You cannot edit settings from this

screen. This can only be done via GenLink. Data has been divided

up into groups and each group is shown as a button on the menu

screen. Touching the button will take you to the main screen for

the group. Some groups such as diagnostics may also have sub

screens associated with them. Each screen has some fixed but-

tons which allow you to either access help text for that screen

(context sensitive help) or return to the main menu (Figures 3.23,

3.24 and 3.25).

Figure 3.23 — Help & Return to Main

Menu Keys

RETURN TO MAIN

MENU KEY

HELP KEY

Operation

Содержание PowerManager 004975-2

Страница 25: ...23 Notes...

Страница 26: ...24 Notes...

Страница 27: ...25 Notes...

Страница 28: ...26 Installation Diagrams NEMA 1 Drawing No 0E7619 C...

Страница 29: ...27 NEMA 1 Drawing No 0E7619 C Installation Diagrams...

Страница 30: ...28 Installation Diagrams NEMA 3R Drawing No 0H3175 A...

Страница 31: ...29 NEMA 3R Drawing No 0H3175 A Installation Diagrams...

Страница 33: ......

Страница 34: ......

Страница 35: ......

Страница 36: ......

Страница 37: ......

Страница 38: ......

Страница 39: ......

Страница 40: ......

Страница 41: ......

Страница 42: ......

Страница 43: ......

Страница 44: ......

Страница 45: ......

Страница 47: ......

Страница 48: ......