P a g e

|

44

Réf. : 450100 FR

CHAPTER 6 – Accessories and options

6.1 – Optional equipment

6.1.1 – Take-off unit

Machines equipped with a take-off unit require two operators for use with

the grinding hose.

■

Assembling the hose

Having first checked that the petrol tank is not too full to avoid fuel leaks

(if applicable), reassemble the wheel so that it is retracted as far as possible

inside its protective guard.

Tilt the machine to the operating arm side so as to make the take-off unit

accessible. Remove the take-off unit protective cap and fasten the hose

drive.

■

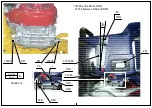

Starting the engine

If the hose is equipped with a clutch

(compulsory for EC use)

, use of the

take-off unit only calls for one operator.

Two operators are required if the hose has no clutch. The first operator

who fastened the selected tool must take over control of the wheel-holder

and wait for operation to start, controlled by the second operator. He must

not put down the wheel-holder until the engine has been completely

stopped by the second operator. As long as the engine is running, one of

the operators must remain in place close to the engine in order to stop it

immediately should an incident of any kind occur.

■

Precautions of use

During grinding, take all necessary precautions to avoid directing the spark

jet towards the second operator (he must be equipped with goggles and

gloves).

Do not bend the hose excessively, as this could damage the drive and, in

some cases, lead to accidents in the case of sudden breakage due to

improper use.

After stopping the engine, the hose shall be disassembled, and the take-

off cap properly put back in place. To continue work, put the machine back

on the track prior to operation.

■

Take-off unit

(ref. 37000 DS – addition to the original supply)

Hoses

(for use of wheel-holders)

Hose without clutch

Hose with clutch

(Compulsory for EC machines

equipped with take-off device)

3 m long (ref. 16300 A)

3 m long (ref. 16300 E)

4 m long (ref. 16300 B)

4 m long (ref. 16300 G)

Reinforced resin bonded wheel

(for wheel-holder with hose)

- For straight wheel-holder 230 x 20 x 16 mm (code N00742);

- For wheel-holder with bracket return 230 x 6.4x 22.2 mm (code

N00730);

- For wheel-holder with bracket return 150 x 72 mm (code N00734).

Wheel-holders for hoses:

- Straight wheel-holder for grinding of device cores, and rail web and

ends (ref. 600 W);

- Wheel-holder with bracket return, for weld grinding (ref. 600 X);

- Wheel-holder with bracket return, for weld grinding (ref. 600 Y).

Stop the engine before working on the wheel or hose.

Содержание MP.12

Страница 50: ...K K ...

Страница 54: ......

Страница 56: ......

Страница 60: ...37000 QD R 05 19 QRH 37699 QRH PX NCN DBU CSS NCN DBU 37706 37701 KIH FG AF GRY FM FG LBG 400119 Feuille 2 4 ...

Страница 64: ...37000 QE R 05 19 PTH NEQ NEA noir black rouge red jaune yellow noir black M Feuille 1 2 ...

Страница 65: ......

Страница 66: ...37717 JZH 37000 QE R 05 19 Feuille 2 2 ...

Страница 68: ......

Страница 70: ......

Страница 72: ......

Страница 76: ......

Страница 77: ......

Страница 78: ......