P a g e

|

36

Réf. : 450100 FR

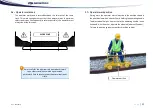

5.1.5 – Drive belt tension

(must be carried out with the engine stopped)

Belt tension is given by the variation in pitch diameter of pulleys by

means of wedge sets. The drive pulley and the driven pulley are both

adjustable. To access the pulleys, disassemble the wheel, the wheel

casing and the belt casing.

Every 50 operating hours, check belt tension and adjust if necessary as

follows:

-

Disassemble the flange from the pulley Item

①

held by nuts Item

③

.

-

Remove a wedge Item

②

.

-

Reassemble the flange Item

①

placing the wedge Item

②

between

the flange and the nuts Item

③.

-

Progressively tighten the six nuts Item

③

, while rotating the pulley

manually so that the belt assumes its position without being stuck

between the two flanges.

If the resulting tension is not sufficient, repeat the operation

.

To guarantee proper belt alignment, the same adjustment must be performed

on each pulley.

When there are no more wedges between the flanges of the two pulleys and

the belt spins, the belt must be replaced with a new belt.

To assemble a new belt, fit all the wedges (2 per pulley) between the pulley

flanges.

Run a first belt tension check after 10 hours’ use of the machine, then check

and adjust tension if necessary every 50 hours.

NEW BELT

WORN BELT

1

2

3

2

1

When replacing or putting back a belt, check that the pulley

grooves are in proper condition and clean them as well as the

belt grooves thoroughly.

Содержание MP.12

Страница 50: ...K K ...

Страница 54: ......

Страница 56: ......

Страница 60: ...37000 QD R 05 19 QRH 37699 QRH PX NCN DBU CSS NCN DBU 37706 37701 KIH FG AF GRY FM FG LBG 400119 Feuille 2 4 ...

Страница 64: ...37000 QE R 05 19 PTH NEQ NEA noir black rouge red jaune yellow noir black M Feuille 1 2 ...

Страница 65: ......

Страница 66: ...37717 JZH 37000 QE R 05 19 Feuille 2 2 ...

Страница 68: ......

Страница 70: ......

Страница 72: ......

Страница 76: ......

Страница 77: ......

Страница 78: ......