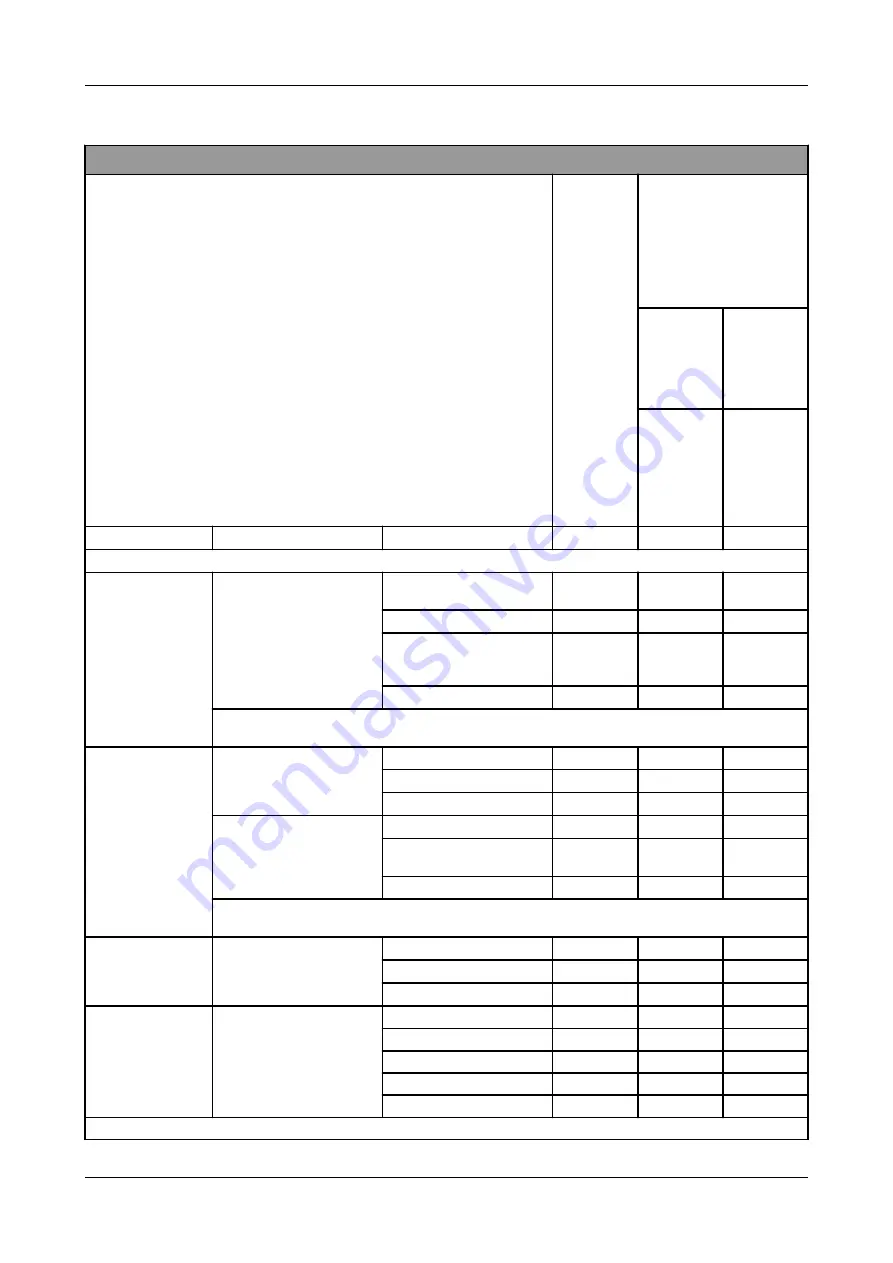

3.4.3.2 Maintenance table V (HS, HP) Series, part 2 of 3

GEA Grasso Maintenance intervals, part 2 of 3

GEA GRASSO MAINTENANCE INTERVALS AND ACTIVITIES

Whatever

comes first:

Yearly or

every

6.000 hr at

1200 RPM

5.000 hr at

1500 RPM

Flexible:

Depending on running

conditions and shown by

GMM or OMNI

- - - - - - - - - -

Fixed:

To be monitored by

operator

Flexible

interval:

VM 6.000 -

18.000 hr

VL 7.500 -

18.000 hr

Flexible

interval:

VM 40.000 –

47.000 hr

VL 40.000 –

54.000 hr

Fixed

interval:

12.000 hr at

1200 RPM

- - - - -

10.000 hr at

1500 RPM

Fixed

interval:

36.000 hr at

1200 RPM

- - - - -

30.000 hr at

1500 RPM

Main system

Sub system

Mechanical part

A

B

C

CYLINDER LINERS

Inner surface honing profile

2)

INSPECT

MEASURE

MEASURE

Suction valve seats

INSPECT

INSPECT

Push rods suc. valves

capacity regulation / lifting

mechanism

INSPECT

INSPECT

Camring

INSPECT

Note:

For A maintenance keep inspection limited to 1 or 2 most frequently activated cylinders or cylinder(s)

nearest to the compressor’s shaft end. Refer Section 3.4.3.4, Page 48

PISTON &

CONNECTING ROD

ASSEMBLY

Piston assembly

Piston body

INSPECT

INSPECT

Piston rings

INSPECT

REPLACE

Gudgeon pin

INSPECT

MEASURE

Connecting rod assembly

Small end bearing bushing

INSPECT

MEASURE

Tightening conn.rod bolts &

nuts

Big end bearing shells

INSPECT

REPLACE

Note:

For B maintenance keep inspection limited to 1 or 2 most frequently activated cylinders or cylinder(s)

nearest to the compressor’s shaft end. Refer Section 3.4.3.4, Page 48

MAIN BEARINGS

Main bearing oil pump side

INSPECT

Intermediate bearings

INSPECT

Main bearing drive side

INSPECT

CRANKSHAFT

Main bearing journals

MEASURE

Conn.rod bearing journals

MEASURE

Shaft seal journal

INSPECT

Trust bearing

INSPECT

Shaft seal

INSPECT

INSPECT

REPLACE

MAINTENANCE

SERVICE MAINTENANCE SCHEDULE

P-NL-094_imm_VHS_English_13

26.07.2021

47