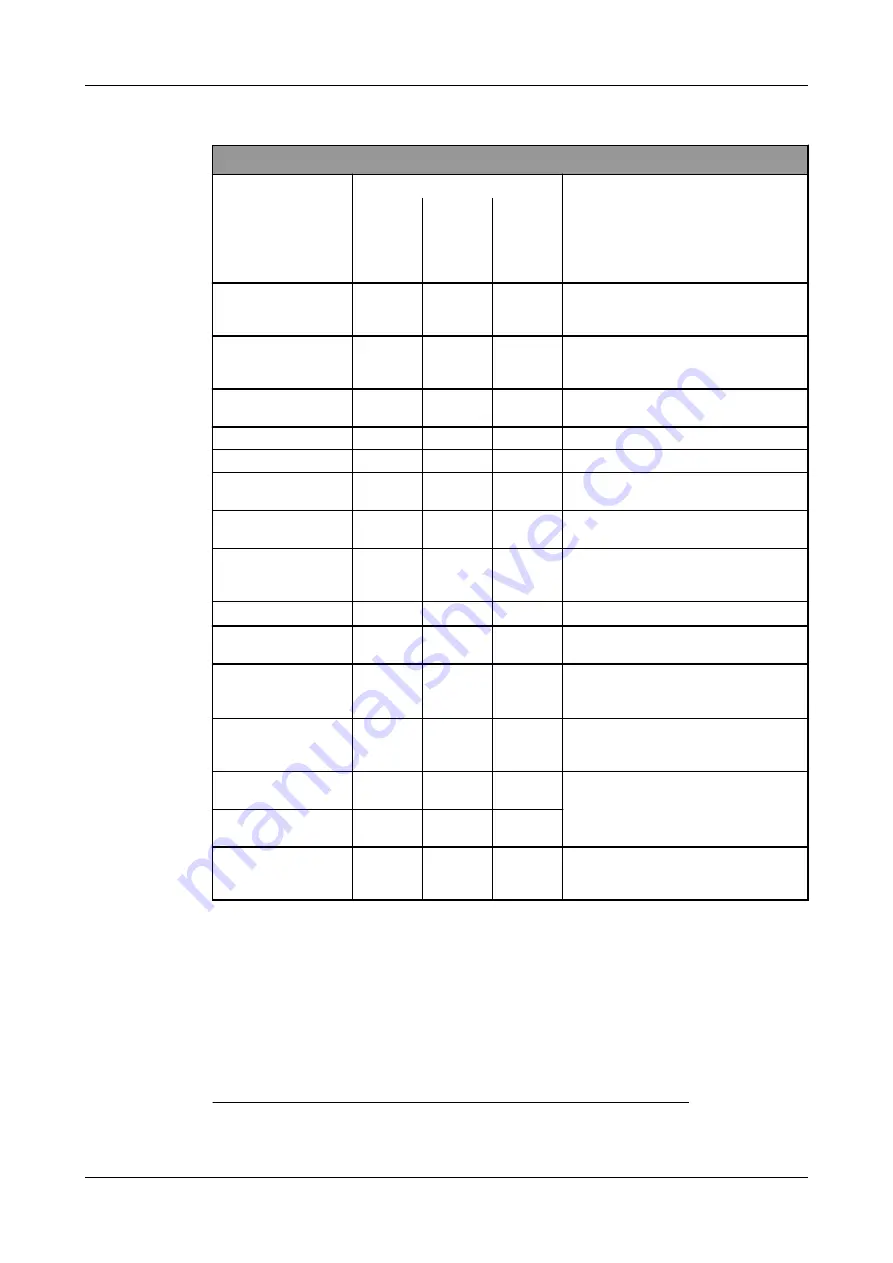

2.2.1

Check list periodical inspection

Check list periodical inspection

CHECK POINTS *

5

FREQUENCY

REMARKS

daily

weekly

monthl

y

Oil level in crankcase

•

Between 25% and 75% height of the sight

glass. For topping up oil, refer to

Section 2.4.1, Page 34.

Colour of the oil

•

The oil should be transparently clear. A

disappearing white colour points to

dissolved refrigerant.

Lubricating oil pressure

difference

•

Min. control oil pressure

•

Oil temperature max.

•

Refer to the "Product Information"

Oil leakage of shaft seal

max.

•

In case of more than 1 cc/hr contact

supplier.

Suction pressure

•

Check against design conditions. Refer to

plant manual.

Discharge pressure

•

Refer to plant manual. For the max.

allowable discharge pressure refer to the

technical data of compressor.

Suction superheat

•

≥0 K (NH

3

)

Discharge temperature

max.

•

170 °C.

Oil temperature min.

•

During compressor standstill the lower part

of the crankcase must remain warmer than

the surroundings: ≥ 20 °C (NH

3

)

Adjustment and

operation of pressure

safety switches

•

Refer also to instructions of switch

manufacturer.

Capacity control (if

provided)

•

Switching frequency of

the compressor

•

Number of operating

hours

•

Check the number of operating hours in

view of any maintenance operations to be

carried out.

2.3

STEPS FOR LONGER SHUT-DOWN PERIODS (> 6 months)

To shut down a compressor for long term periods, proceed as follows:

i.

Tightly shut both the suction and discharge stop valves and the stop valve of

the oil return line (if present).

ii.

Disconnect the power source from the compressor drive motor and the

electrical control cabinet.

5

During the first 50 operating hours the compressor should be checked regularly for all the points

mentioned above, at least twice every 24 hours and more frequently in cases where irregularities are

found.

INSPECTION AND TROUBLE SHOOTING

STEPS FOR LONGER SHUT-DOWN PERIODS (> 6 months)

P-NL-094_imm_VHS_English_13

26.07.2021

33