GE H

EALTHCARE

DRAFT

LOGIQ™ S7 E

XPERT

/P

RO

D

IRECTION

5460683

, R

EVISION

3

DRAFT (J

UNE

25, 2014)

S

ERVICE

M

ANUAL

Chapter 4 - Functional Checks

4-15

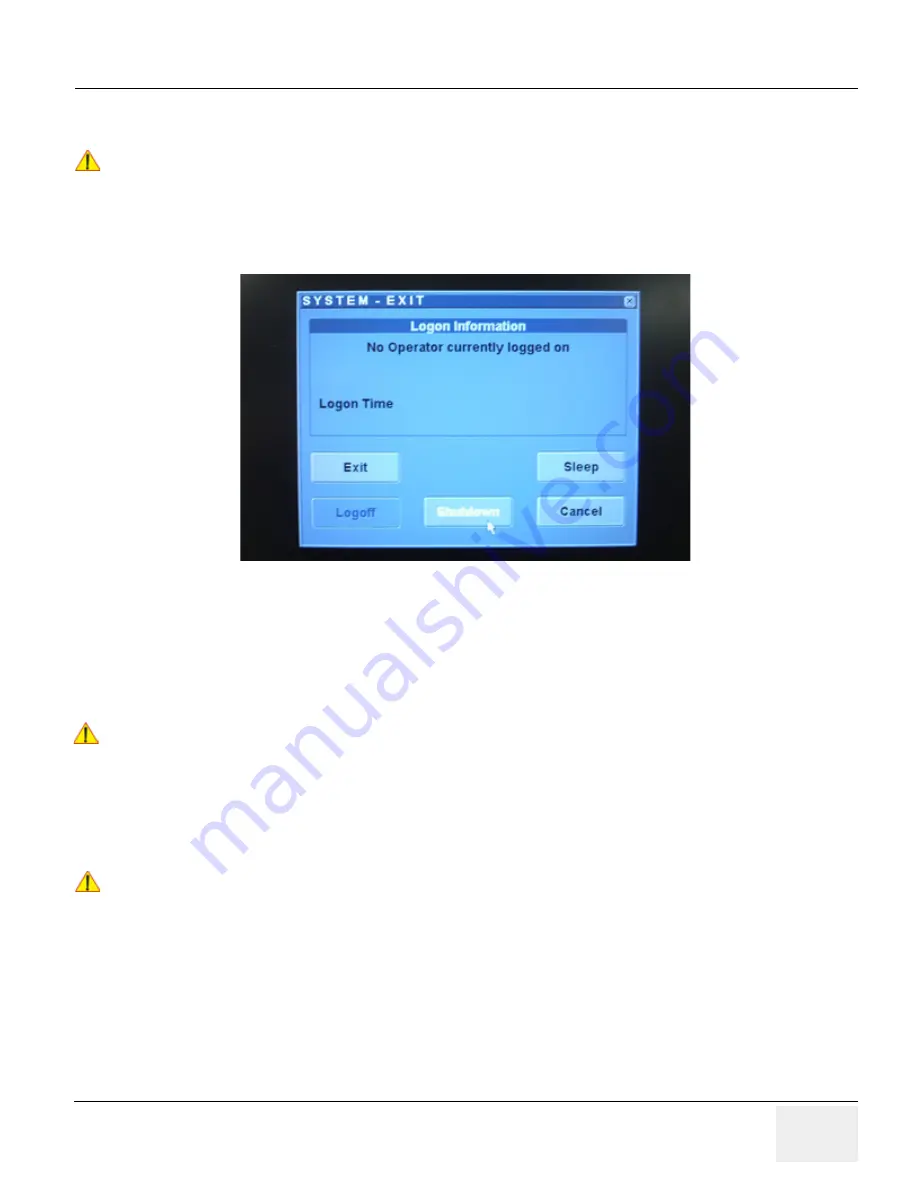

4-3-3-4

Complete power down

1.) If not already in read mode, freeze the image.

2.) When you shutdown the system, enter the scan screen and lightly press the Power On/Off switch

(see:

Figure 4-14

) once. The System-Exit window is displayed.

Figure 4-14 Power OFF User Interface

3.) Select the SHUTDOWN button. The system performs an automatic full shutdown sequence.

4.) Switch OFF the Circuit Breaker at the rear of the system.

NOTE:

The mains outlet of the system for peripheral auxiliary equipment are commonly switched with the ON/

OFF button. So the auxiliary equipment need not to be switched ON/OFF separately.

5.) After complete power down, unscrew the 2 screws and remove the pull-out protection to disconnect

the main power cable from the system or unplug it from the AC wall outlet socket.

6.) Press on the brakes to block the front caster wheels.

7.) Disconnect probes.

NOTICE

!! NOTICE:

After turning off a system, wait at least 10 seconds before turning it on again. The system may not be

able to boot if power is recycled too quickly.

WARNING

WARNING

!! WARNING:

Disconnection of the Main Power Cable is necessary!

For Example: When repairing the system.

NOTICE

!! NOTICE:

Be sure to follow probe handling instruction and caution outlined in Basic User Manual.

Содержание LOGIQ S7 Expert

Страница 2: ......

Страница 11: ...GE HEALTHCARE LOGIQ S7 EXPERT PRO DIRECTION 5460683 REVISION 3 SERVICE MANUAL ix ZH CN KO ...

Страница 38: ...GE HEALTHCARE LOGIQ S7 EXPERT PRO DIRECTION 5460683 REVISION 3 SERVICE MANUAL xxxvi Table of Contents ...

Страница 434: ......