- 52 -

232001280G(13)

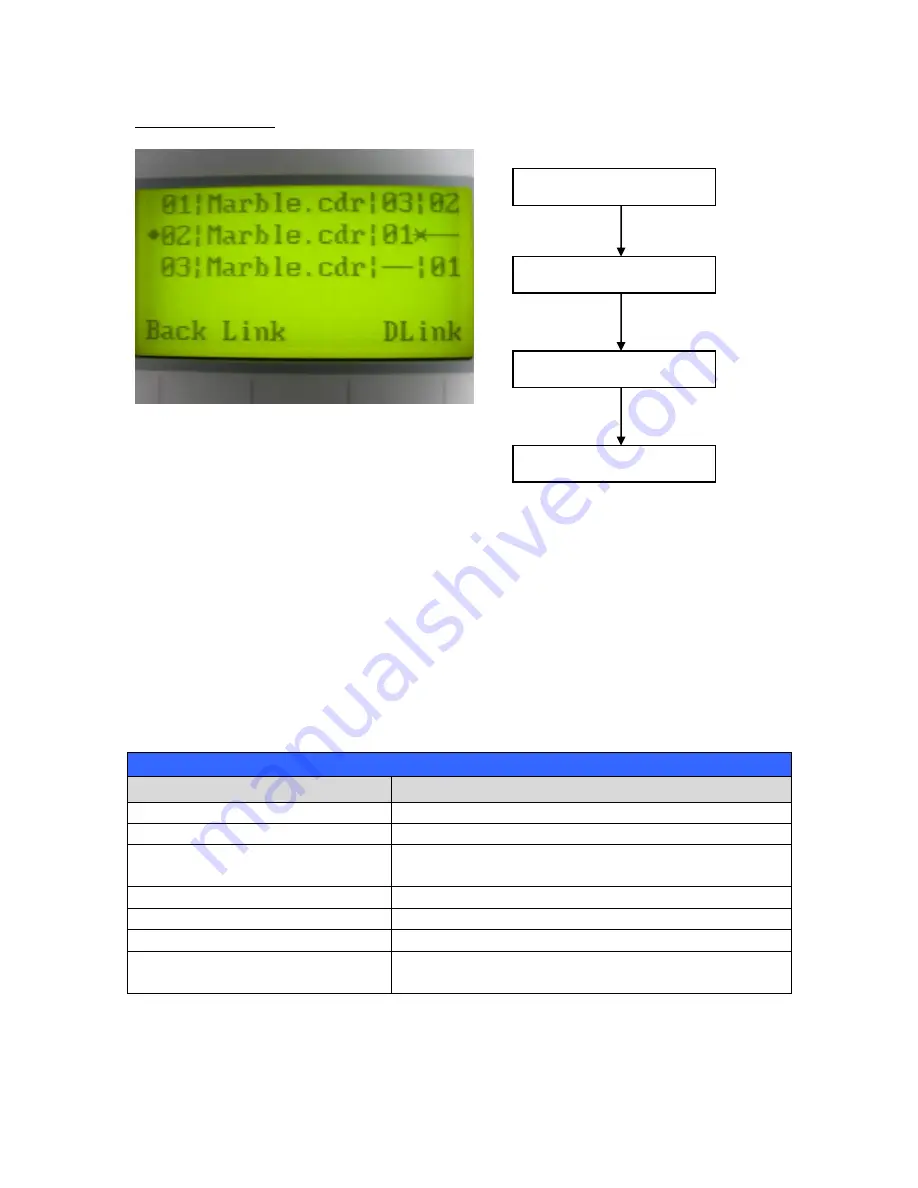

Link/DLink Page

The Link/DLink Page allows you to set, arrange, and remove loaded jobs to and from a job queue

for processing. Use the directional keys to cycle through your loaded jobs, then simply press the

<F2 (Link)> key to add a file to the job queue. The job queue will be set in a sequential order

based on the order you link the files. To remove a job from your job queue, press the <F4

(DLink)> key.

The first column field (before the file name) displays the job number. The sequence for your job

queue is displayed in the two columns to the right of your file names. The first column to the right

of your job file name displays the job number of the previous file in the job queue sequence. The

second column after the file name displays

that job’s next file in the job queue sequence. First

and last jobs in the job sequence you set will have a (---) in the first and second columns

respectively. So according to the image above, the job queue sequence has been set to be

processed in this order: 03:Marble.cdr

01:Marble.cdr

02:Marble.cdr.

Link/DLink Page

Relevant Buttons

Function

F1 (Back)

Back to previous page

F2 (Link)

Add the currently-selected job to the job queue

F4 (DLink)

Remove the currently-selected job from the job

queue

/

Directional

Scroll through your loaded jobs

Start / Stop

Back to Main Work Page

Auto Focus

Initiate the auto focus function

▲ / ▼

Manual Focus Buttons

Manually adjust the height of the work table (Z-

axis)

Main Work Page

Press

F4

☼

Navigating to this page:

Functions Page

Select <

File Management

>

from the menu

File Management Page

Press

F2

Link / DLink Page

Содержание LaserPro Venus II

Страница 1: ......

Страница 17: ... 17 232001280G 13 ...

Страница 18: ... 18 232001280G 13 ...

Страница 23: ... 23 232001280G 13 ...

Страница 24: ... 24 232001280G 13 ...

Страница 32: ... 32 232001280G 13 5 Press Active 6 Press OK when activation is complete 7 Register Parallels Desktop ...

Страница 82: ... 82 232001280G 13 ...

Страница 92: ... 92 232001280G 13 ...

Страница 103: ... 103 232001280G 13 7 Finally Invert the image by selecting Effects Transform Invert ...