Instructions for GT1000DC

www.gatexpertstore.com

8

Step 4 - Motor Pad Footing

·

The motor pad concrete footing requires an area of no less than 450mm long x300mm wide

and a minimum depth of 200mm (Standard requirement).

·

Ensure surface is level and parallel to the driveway.

Mounting Plate Dimensions

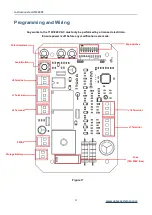

Figure 8

Step 5 - Fitting Mounting Plate and Motor

Without Mounting Plate

·

Pre embed the anchor bolts according to holes in motor base before concerting (as per Figure

9).

·

Afater concrete hardening, bolt the motor with M10x50mm bolts, spring and flat washers

provided and tighten as required. (The height can be slightly adjusted by bottom bolts as per

Figure 10).

Figure 9

Anchor bolts